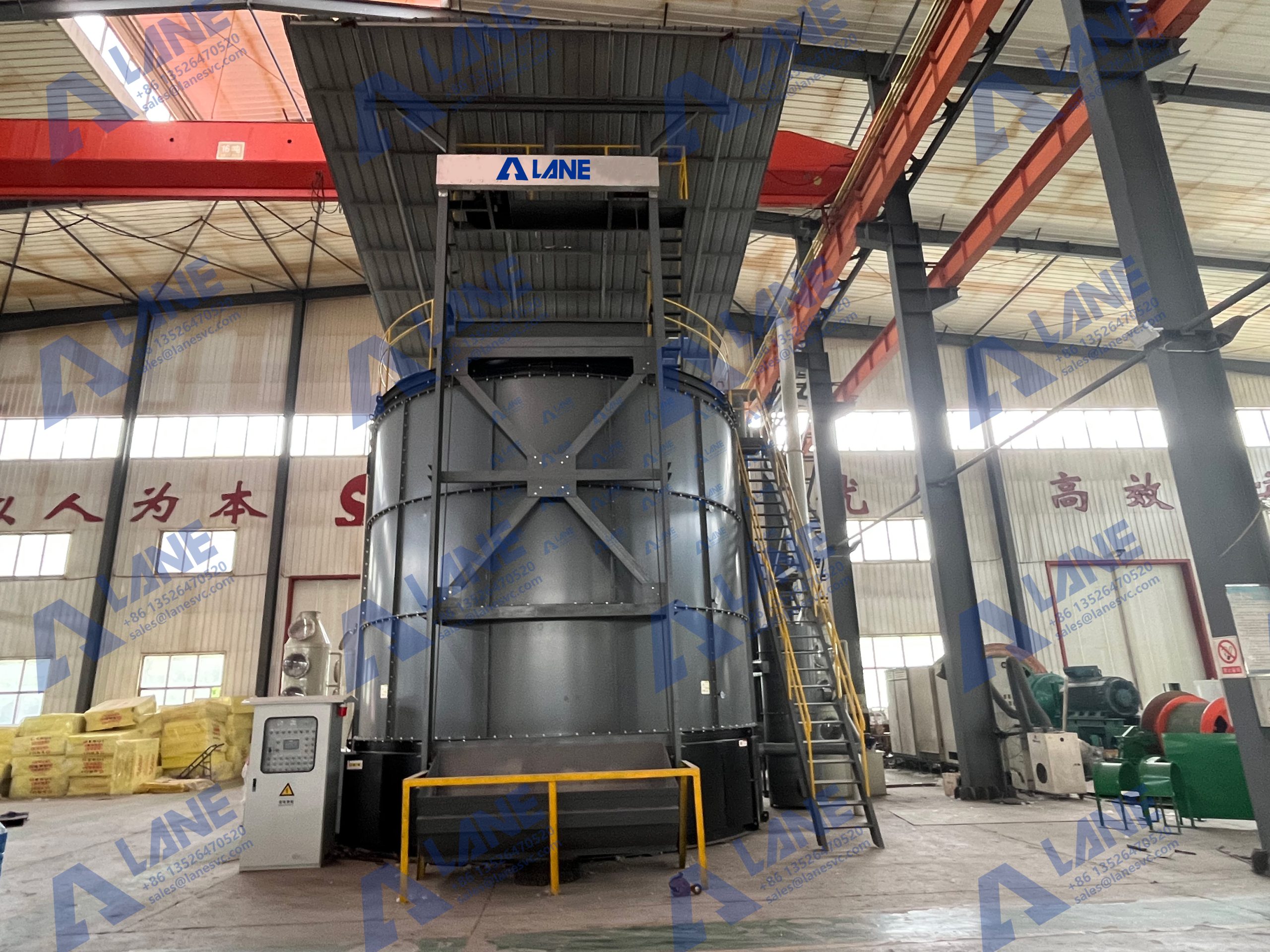

Vertical fermentation tank is a professional equipment in organic fertilizer production line, it has advanced technology, can well ferment organic raw materials, so that the raw materials in specific temperature and humidity conditions to produce chemical reactions, to achieve the desired results, to create excellent conditions for the pelleting process later, to produce organic fertilizer particles rich in elemental content.

Crop Residues: Such as crop stalks, leaves, and other plant materials.

Manure: Livestock manure (e.g., cow, poultry, or pig manure) is a rich source of organic matter.

Food Waste: Organic kitchen scraps, vegetable peels, and leftover food.

Garden Waste: Grass clippings, tree trimmings, and garden debris.

Sawdust or Wood Chips: These materials provide carbon and help balance the carbon-to-nitrogen (C/N) ratio in the compost.

Paper and Cardboard: Shredded paper and cardboard can be added as a source of carbon.

| Model | Hopper Volume(m³) | Volume Of Fermentation silo(m³) | Blower power(kw) | Motor Power(kw) | Water Content 50%-65% Treatment Capacity(t) | Water Content 50%-65% Output Capacity(t) | Water Content 60%-70% Treatment Capacity(t) | Water Content 60%-70% Output Capacity(t) | Size(mm) |

| LAF-120F | 1.5 | 120 | 15 | 10 | 12-16 | 4.3-6 | 10-14 | 3.3-5 | 7500*8000*9400 |

| LAF-100F | 1.5 | 100 | 11 | 7.5 | 10-14 | 3.5-5 | 8-12 | 2.5-4 | 7000*8000*9000 |

| LAF-86F | 1.5 | 86 | 11 | 7.5 | 8-12 | 2.7-4 | 7-9 | 2-3 | 7000*8000*8700 |

Vertical fermentation tank, also known as vertical composters or aerobic fermenters, are designed to promote the decomposition of organic matter into nutrient-rich compost under aerobic conditions. The principle of operation includes the following key steps:

1) Loading: Organic materials are loaded into the vertical tank.

2) Aeration: The tank is equipped with an aeration system that introduces oxygen into the compost. This promotes the growth of aerobic microorganisms (bacteria, fungi) that break down organic matter.

3) Temperature Control: Some digesters are equipped with a temperature control system that maintains the compost temperature within an optimal range (usually between 130°F and 160°F or 55°C and 70°C) to accelerate decomposition.

4) Turning or mixing: To ensure uniform decomposition and aeration, some vertical digesters are equipped with devices to turn or mix the compost material.

5) Humidity Control: Maintain proper humidity (usually about 50-60%) in the tank to support microbial activity. Water may be added as needed.

6) Maturation: After the composting process is complete (usually within a few weeks to a few months), the compost is allowed to mature and cool.

Vertical fermentation tank offer several advantages in organic fertilizer production line:

1) Space efficiency: Vertical digesters require less horizontal space than the traditional windrow composting method, making them suitable for use in urban or space-constrained areas.

2) Odor Reduction: The enclosed design of the vertical digester helps to suppress odors generated during the composting process, making it suitable for areas where odor control is required.

3) Temperature Control: Some models offer precise temperature control for faster, more efficient composting.

4) Aeration Control: These composters are often equipped with automatic aeration systems that can be fine-tuned to optimize microbial activity.

5) Efficient Decomposition: The controlled environment in a composting tank facilitates efficient decomposition, resulting in high quality compost.

6) Consistency: Vertical composting tanks produce consistent, uniform compost.

7) Reduced Labor: Automation features reduce the labor required for manual turning and monitoring.

All in all, if you plan to build an organic fertilizer production line with large output, long use and abundant raw materials, buying a vertical fermenter is definitely the right choice, which can bring great advantages and competitiveness to your organic fertilizer production.

If you have any questions about the use or purchase, please feel free to contact us, our customer service all day online for you to answer!