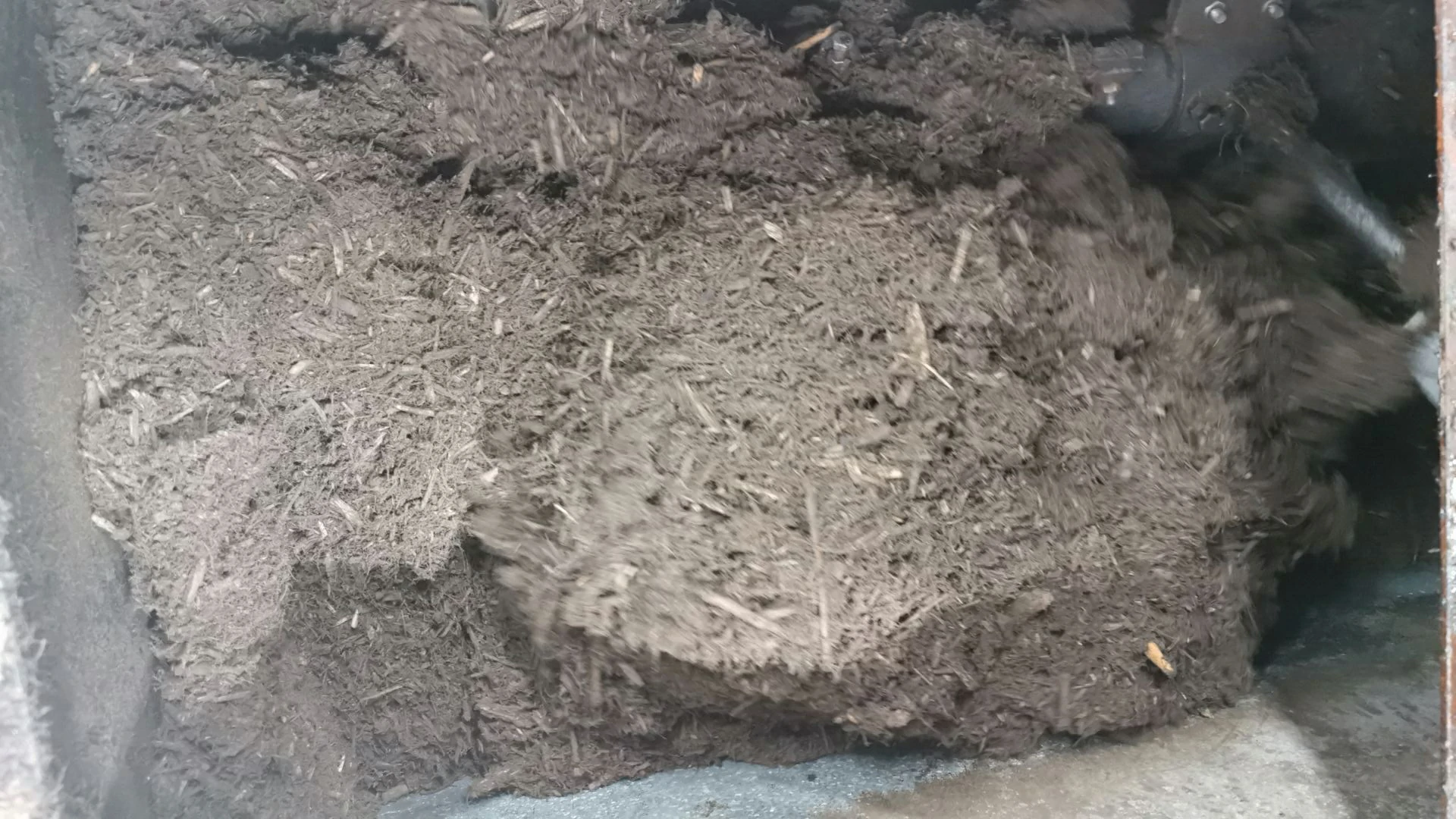

Organic fertilizer horizontal fermentation tank is mainly for livestock and poultry manure, food waste and other organic wastes, high temperature aerobic fermentation, the use of microbial activity of organic matter in the waste biological decomposition, so as to achieve harmlessness, stabilization, reduction, resource utilization of the integrated processing equipment.

Organic waste requires proper conditions of temperature, humidity and oxygen supply during the fermentation process to ensure the quality of fermentation.

Equipped with advanced automatic control system, this series of horizontal fermentation tank can monitor and regulate these key parameters to ensure the stability and quality of the fermentation process, avoiding fermentation failure or substandard quality, which plays a vital role in the organic fertilizer production line.

| Model | Overall Size(mm) | Volume Of Fermentation silo(m³) | Motive Power(kw) | Heating Power(kw) | Fermentation Period(day) |

| LAHF-3F | 3500*1550*2200 | 3.1 | 3 | 3 | 7-10 |

| LAHF-5F | 3500*2000*2500 | 6.5 | 4 | 6 | 7-10 |

| LAHF-10F | 3500*2400*2900 | 10 | 5.5 | 11 | 7-10 |

| LAHF-20F | 5500*2600*2900 | 20 | 11 | 22 | 7-10 |

| LAHF-30F | 6000*2900*3500 | 30 | 15 | 30 | 7-10 |

1) Collect livestock and poultry manure back from farms and straw, edible fungus dregs and other wastes from rural areas, air-dry and crush them.

2) According to the fixed formula ratio of livestock and poultry manure 70%, smoke end, straw 30% mixed to join the high-speed fermentation equipment, and in the horizontal fermentation tank at the ratio of 1:1000 to add the VT-1000 type fermentation strain.

3) The moisture of the material in the mixing tank is controlled at about 60% through the mixing tank.

4) After heating to 90 degrees of heat conduction oil into the fermentation tank outside the sandwich, through the role of heat conduction heating, the temperature of the material in the fermentation tank to about 80 ℃.

5) Keep it for 3 hours, and then cut off the power to keep the temperature between 65℃-80℃, meanwhile the stirring equipment in the fermentation tank is intermittently stirring, the whole fermentation time in the fermentation tank is about 3-6 days.

6) The horizontal fermentation tank is distributed with 32 oxygenation pipes, which are distributed at intervals according to the up and down, each with 16 oxygenation pipes and staggered up and down position.

7) According to the fermentation process requirements of compressed air from the oxygenation pipeline oxygenation at regular intervals.

8)Automatic control of temperature, moisture, CN ratio, oxygen content, PH value, ripening degree, electric heating and air flow equipment operation in the fermentation process of cow dung in the fermentation tank.

1) Horizontal fermentation tank has two kinds of U-type and column type, screw belt mixing blade and transmission parts; U-shaped long cylinder structure, to ensure that the mixed material (powder, semi-fluid) in the cylinder body of the small resistance to movement.

2) Forward and backward rotating screws are installed on the same horizontal axis, forming a low-power and high-efficiency mixing environment, and the ribbon blade is generally made into a double or triple.

3) The outer screw converges the materials from the two ends to the center, and the inner screw disperses the materials from the center to the two ends, which can make the materials form more vortex in the flow, speed up the mixing speed and improve the mixing uniformity.

4) Horizontal fermentation tank can be heated by electric heating, oil-conducting heating or steam heating.

5) Cooling process can be directly injected into the jacket cooling water, jacket heat transfer area is large, cooling speed.

6) Small-sized horizontal fermentation tank adopts direct connection of reducer, with simple structure, high operational reliability and convenient maintenance.

7) The large-sized horizontal fermentation tank is driven by a cycloidal reducer driven by a belt pulley. The elastic connection of the belt drive has the advantage of protecting the drive parts in case of overload.

8) Horizontal fermentation tank fermentation covers an area of 30-50 square meters, can be a multi-purpose machine, set of feed fermentation, organic fertilizer fermentation, sick and dead pig treatment multi-functional as a whole.

All of our products undergo strict quality inspection, support remote inspection, short delivery cycle, long service cycle, and we look forward to establishing a long cooperative relationship with you!