In the production process of sugar industry, every 1 ton of white sugar will produce about 300 kg of sugar residue. These seemingly useless industrial wastes can be transformed into highly efficient organic fertilizer through professional sugar residue organic fertilizer production equipment and process. This article will introduce in detail the complete production process and key equipment from sugar residue to organic fertilizer particles, highlighting the application and selection of sugar residue organic fertilizer production equipment.

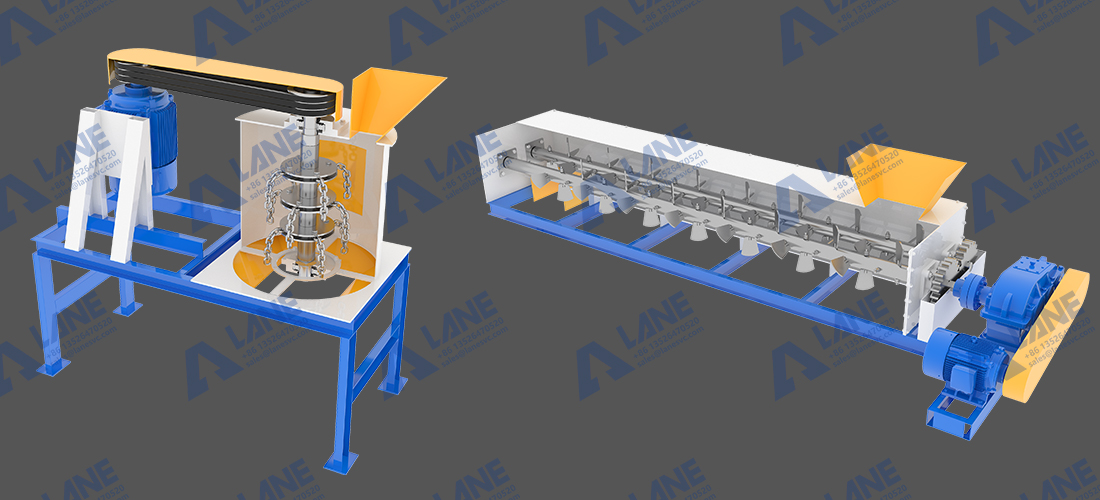

Pre-treatment stage mainly uses crusher and mixer, which is the basic link in the sugar residue organic fertilizer production equipment. The crusher adopts hammer blade structure, which can crush the sugar residue to 5-10mm particle size, and improve the efficiency of subsequent fermentation. The mixer is used to adjust the carbon and nitrogen ratio, usually using a double shaft paddle mixer to ensure that the sugar residue and nitrogen sources are evenly mixed.

Suggestions for equipment selection: small and medium-sized production lines use 15-22kW crusher, processing capacity of 2-3 tons / hour; mixer volume selection of 3-5m³, equipped with 7.5-11kW motor. Operation should pay attention to control the moisture content of the material in 50-60%, in order to obtain the best mixing effect.

Fermentation tank is the core equipment for aerobic fermentation and an important part of the sugar residue organic fertilizer production equipment. There are common trough fermentation system and tower fermentation system. Tank system using concrete or steel plate structure, equipped with compost turner and aeration system, single tank volume is usually 50-200m³. The tower system is a multi-layer three-dimensional structure, covers a small area, high degree of automation, but the investment cost is larger, the main equipment includes vertical fermenter, horizontal fermenter, rotary drum fermenter.

Turning equipment includes chain plate compost turner, crawler compost turner, knife and axe compost turner and so on. Chain plate type is suitable for wide trough fermentation, and the turning width can be up to 6-8 meters; crawler type has strong maneuverability and is suitable for multi-trough operation. The aeration system mostly adopts Roots fan, supplying oxygen to the material through the aeration pipe arranged at the bottom of the tank, and the air volume is configured according to 0.05-0.1m³/min-m³ material.

The temperature control system includes temperature sensors and automatic control devices, which can monitor and regulate the fermentation temperature in real time. It is recommended to use multi-point temperature measurement, set one temperature measurement point every 50m³ to ensure the temperature control within 55-65℃.

Granulation pre-treatment equipment including dryers and fine crusher, which is the key link in the sugar residue organic fertilizer production equipment. The dryer is mostly used drum type, the moisture content of the material down to 12-15%; fine crusher using vertical chain mill, crushing fineness of 40-60 mesh, to ensure the quality of granulation.

Granulation equipment mainly includes churning tooth granulator and rotary churning tooth two-in-one granulator, which is one of the core equipment in sugar residue organic fertilizer production equipment.

Churning teeth granulator through the high-speed rotation of the churning teeth will be extruded into particles, suitable for the production of 2-4mm irregular particles, capacity of 1-2 tons / hour, high strength particles, suitable for viscous materials. The rotary drum churning teeth two-in-one granulator combines the advantages of rotary drum granulator and churning teeth granulator, which can produce 2-6mm spherical or columnar granules, with the capacity of 2-3 tons/hour, with strong adaptability, suitable for a wide range of materials.

After the granulation process, the fertilizer particles need to be dried and cooled, and the processing equipment includes dryer, cooler and sifter, which together constitute a complete post-processing system of sugar residue organic fertilizer production equipment.

The dryer adopts drum type, the temperature is controlled at 80-100℃, and the moisture content of the granules is reduced to less than 8%. Cooling machine mostly used counter-current type, the temperature of the particles down to room temperature. The sieving machine adopts double-deck tumbler sieve, the upper layer sieves out oversized particles, and the lower layer sieves out powder to ensure the uniformity of the finished product size.

Coating equipment is used to improve the quality of granules, commonly used drum type coating machine, can add anti-caking agent or functional bacterial agent. Packaging equipment selection of automatic quantitative packaging machine, packaging specifications 25-50kg / bag, equipped with automatic weighing and sewing function, packaging accuracy ± 0.2kg.

Sugar residue preparation of organic fertilizer particles of the complete production process involves a number of links, each link of the sugar residue organic fertilizer production equipment selection and process control have a direct impact on the final product quality. With the progress of technology, more intelligent, energy-saving equipment will be applied to the field, to promote the resource utilization of sugar residue to a more efficient, more environmentally friendly direction.

It is recommended that enterprises in the selection of equipment, give full consideration to their own needs and future development, choose the most suitable process route and equipment configuration. Through scientific equipment selection and process optimization, sugar residue organic fertilizer production equipment will create greater economic value and environmental benefits for enterprises.