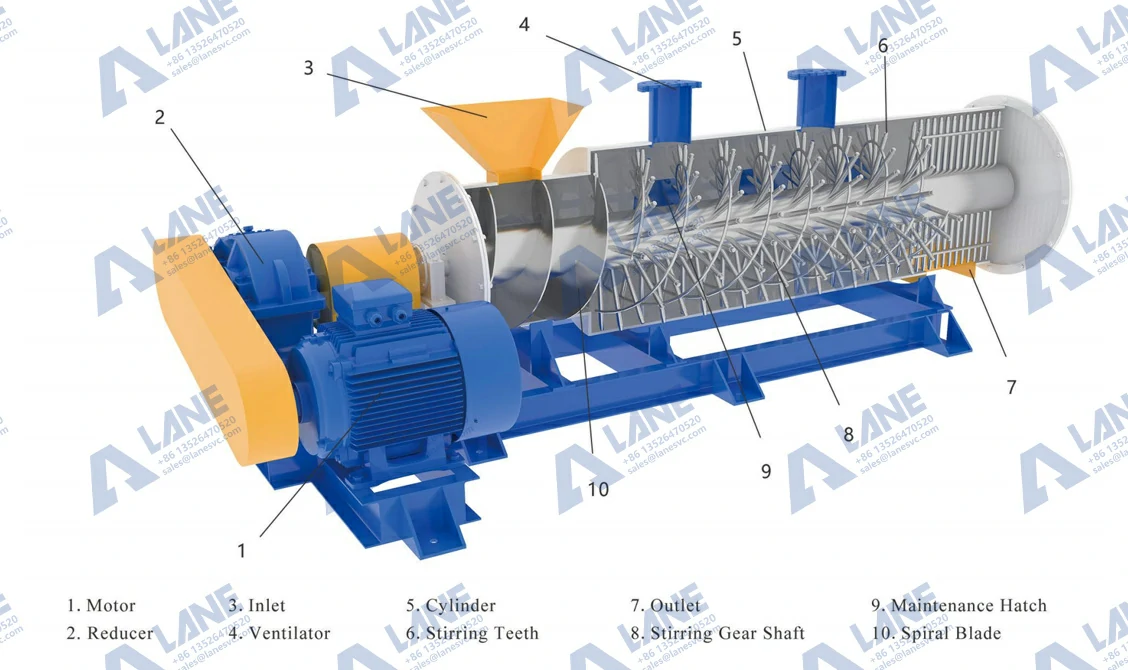

New organic fertilizer granulator, also known as churning teeth granulator, is the key granulation equipment for organic fertilizer production line.

1) The principle of new type organic fertilizer granulator is simple and the granulation speed is fast.

2) It uses high-speed rotating mechanical stirring force and the resulting aerodynamic force to make the fine powdery materials in the machine to continuously realize the process of mixing, granulation, spheroidization, densification, etc., so as to achieve the purpose of granulation.

3) It is suitable for the production of organic fertilizer with high moisture content and high quality granulation.

| Model | Size(mm) | Drum size(mm) | Mixing Shaft(mm) | Capacity(tph) | Power(kw) |

| LAZJ-600 | 4500*1500*1050 | Φ600*1800 | 219*10 | 1-2 | 37 |

| LAZJ-800 | 4900*1700*1250 | Φ800*2400 | 245*10 | 2-3 | 45 |

| LAZJ-1000 | 5300*1900*1400 | Φ1000*3000 | 273*10 | 3-5 | 75 |

| LAZJ-1200 | 5700*2100*1700 | Φ1200*3000 | 325*12 | 6-8 | 90 |

| LAZJ-1500 | 6200*2800*2000 | Φ1500*3000 | 325*12 | 8-10 | 110 |

1) Frame part: all working bodies of the machine are all mounted and fixed on the frame. The machine’s frame are made of medium carbon steel plate, channel steel welded, and through strict quality control and specific process requirements to achieve the purpose of the machine used.

2) Transmission coupling part: the motor drives the pulley, triangle belt, reducer transmission, so that the head work, which transmission reducer and the head work part, with nylon pin coupling engagement transfer drive.

3) Shell part: shell part of the opening with liquid spraying and access door, liquid spraying port is convenient to spray liquid inside to help better molding, access door for the replacement of the churning head is convenient!

4) Churning part: the most important part is the churning part, powder from the feed port into the churning shell through the spiral blade drive, by the churning teeth of the mixing, so as to achieve the purpose of the particles.

1) Organic fertilizer granulator using high-speed rotary mechanical mixing force and the resulting aerodynamic force, so that the fine powdery material in the machine continuously to achieve the process of mixing, granulation, spheroidization, densification and so on.

2) The shape of granulation is spherical, the degree of sphericity ≥ 0.7, the particle size is generally between 0.3-3 mm, the rate of granulation ≥ 90%.

3) The size of the particle diameter can be adjusted by the amount of mixing of the material and the spindle rotation speed, usually the lower the mixing amount, the higher the rotation speed, the smaller the particles, and vice versa.

4) This machine is especially suitable for the granulation of lightweight fine powder materials. The finer the basic particles of fine powder materials are, the higher the sphericity of the particles are, and the better the quality of pelletizing.

When you use the rotary drum churning granulator, please pay attention to these points.

1) Check if there is any debris in the machine before starting.

2) Check if all parts of the machine are in order.

3) It is strictly forbidden to start the machine with load.

4) If the rotation direction is opposite, stop the machine immediately to adjust. Make sure the rotation is smooth, no noise, no friction sound before you start the machine.

5) It is strictly forbidden to bring iron, stone, wood and other debris into the machine in case of damage to the equipment.

6) Before stopping, the inner material must be removed before stopping, to prevent the material from sticking in the cylinder, so as to prepare for the next start, which is beneficial to the production of the next shift.

7) And regular replacement of new lubricating oil, the bearing should be washed when replaced.

8) The speed reducer must be lubricated before use. After 100 hours of the first refueling operation, the oil should be renewed and replaced every four months thereafter, and the oil should be washed when it is exchanged.