Biomass pellet production line is a production system that processes various biomass raw materials (such as wood chips, rice husk, straw, bark, etc.) into biomass pellet fuel. Through mechanical compression and high temperature treatment, the Biomass pellet production line presses the loose biomass raw materials into pellet fuel with high density, high calorific value and easy to store and transport.

| Equipment Name | Key Parameters | Applicable Scenarios/Raw Materials | Notes |

|---|---|---|---|

| Raw Material Crusher | – Power: 30-110kW – Capacity: 1-5 tons/hour – Crushing size: 3-5mm – Dimensions: 3m×1.5m×2m |

Pre-crushing of wood chips, branches, straw, etc. | Hammer/blade crusher options; dust removal system required |

| Rotary Dryer | – Power: 15-75kW – Evaporation capacity: 200-2000kg/h – Heat source: Biomass/natural gas/electric – Temperature: 200-300℃ |

Drying high-moisture raw materials (>15% moisture content) | Moisture content reduced to 8%-12% |

| Pellet Mill | – Power: 90-315kW – Output: 1-10 tons/hour – Die hole diameter: 6-10mm – Pelletizing rate: ≥95% |

Pelletizing wood chips, straw, palm shells, etc. | Core equipment; requires wear-resistant alloy steel dies |

| Cooling & Screening Machine | – Power: 5.5-22kW – Cooling time: 15-30 minutes – Screen mesh size: 3-8mm – Temperature reduction: ≤Ambient +5℃ |

Cooling and impurity removal for storage stability | Air/water cooling options |

| Automatic Packing Machine | – Power: 3-10kW – Speed: 10-40 bags/minute – Weight range: 10-50kg/bag – Precision: ±0.2% |

Quantitative packaging (bagged/bulk) | Stitching or heat-sealing options |

| Electrical Control System | – Control: PLC automation – Voltage: 380V/50Hz (customizable) – Protection rating: IP55 – Energy monitoring: Real-time display |

Integrated line control and fault alerts | Supports remote maintenance interface |

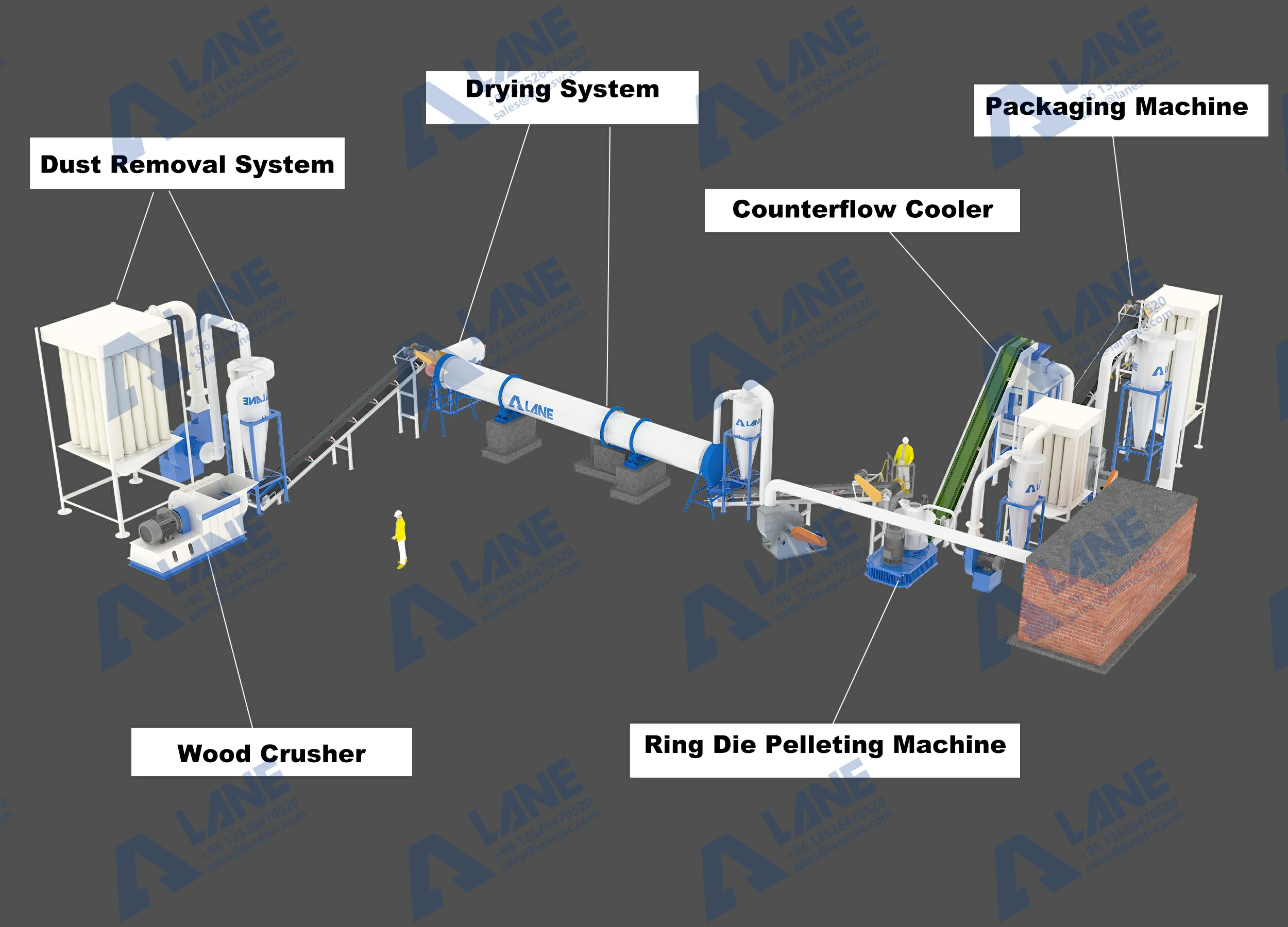

1. Crushing

The wood crusher cuts and crushes the large raw materials into fine particles through the high-speed rotating blades and hammer blades. The crushed particles are usually 5-10mm for subsequent processing.

Parameter specification: processing capacity 1-3 tonnes/hour, power 55 kW.

2. Drying

Burner

Function: Provide high-temperature heat source, burn all kinds of biomass fuels to produce heat energy.

Parameter specification: thermal efficiency above 85%, output thermal power 500-3000 kW, fuel consumption 100-300 kg/h.

Hot air furnace

Function: Convert the heat energy produced by the burner into high temperature hot air for drying raw materials.

Parameter specification: hot air temperature up to 300°C, hot air volume 5000-20000 cubic metres/hour, power 15-75 kW.

Rotary drum dryer is a kind of rotary drying equipment, the raw material enters into the rotary drum from the feeding end, and moves forward with the rotation of the rotary drum, meanwhile, the high temperature hot air passes through the drum from the hot air furnace, so that the raw material and the hot air are in full contact with each other, and evaporate the moisture and reduce the moisture content.

The dried raw material is discharged from the discharging end.

Parameter specification: processing capacity 1-5 tonnes/hour, drum diameter 1.2-2.4 m, length 10-30 m, power 11-55 kW.

3. Pelletising of biomass pellet production line

Ring die pellet machine

Ring die pellet machine uses the relative motion of mould and pressure roller to press the dried raw material into the mould hole, and press the raw material into pellet through high pressure and friction. The pressed pellets are discharged through the mould holes to form biomass pellets.

Parameters and specifications: capacity 1-3 tons/hour, ring die diameter 450-700 mm, die hole diameter 6-10 mm, power 90-132 kW, the specific can be customised according to customer’s needs, the mould is made of wear-resistant steel and stainless steel, stable performance and long service life.

4. Cooling

Counterflow cooler uses the principle of air convection for cooling. High temperature particles enter from the top of the cooler, cooling air enters from the bottom, particles and air flow in the opposite direction, cooling layer by layer. The temperature of the cooled pellets is close to room temperature and discharged from the bottom. Reducing the temperature of the pellets enhances the hardness and stability of the pellets and prevents them from breaking during storage and transport.

Parameter specification: processing capacity 1-5 ton/hour, cooling area 2-8 square metres, cooling air volume 3000-15000 m3/hour, power 1.5-5.5 kW.

5. Packaging

The automatic packing machine packs the cooled biomass pellets into bags through automatic measuring, filling and sealing processes. The packing machine is usually equipped with a weighing device to ensure the accurate weight of each bag of pellets.

Parameter specification: packing speed 5-10 bags/minute, packing weight 15-50kg/bag, power 3-5kw.

1. Efficient production: the production line has a high degree of automation and high production efficiency.

2. Environmental protection and energy saving: equipped with advanced dust removal equipment, reducing dust emission, good environmental performance.

3. High quality of finished products: high pellet density, high combustion efficiency and large calorific value.

4. Easy operation: the production line is simple to operate and easy to maintain, which reduces the labour cost.

5. Widely used: suitable for heating, power generation, industrial boilers and many other fields.

Our biomass pellet production line with professional materials and advanced technology, provide customised service, produce according to demand, five-year warranty, no worries after sale! If you have any questions or needs, welcome to inquire immediately!