Rotary drum dryer is a kind of drying equipment commonly used in fertilizer production line, which is mainly used to dry the fertilizer raw materials with high humidity for subsequent processing and packaging.

The rotary drum dryer is composed of rotating drum, feeding device, discharging device, transmission device, hot gas system and electrical control system. Its working principle is the process that the fertilizer raw material with high humidity enters into the rotary drum through the feeding device and is dried in the rotary drum.

Through the transmission device to drive the rotation of the rotating drum, while the hot gas system will fuel combustion of hot air or water vapor into the rotating drum, the formation of thermal convection, the fertilizer raw materials in the moisture away, so as to achieve the effect of drying. Finally, the dried fertilizer is discharged from the rotor through a discharge device.

This rotary drum dryer is a new generation of rotary drum dryer developed by our staff with years of experience in compound fertilizer production.

The machine has the features of beautiful appearance, simple operation, low energy consumption, long service life, even drying, convenient maintenance, etc. It is the more advanced compound fertilizer drying equipment in China, and the products are all over the country.

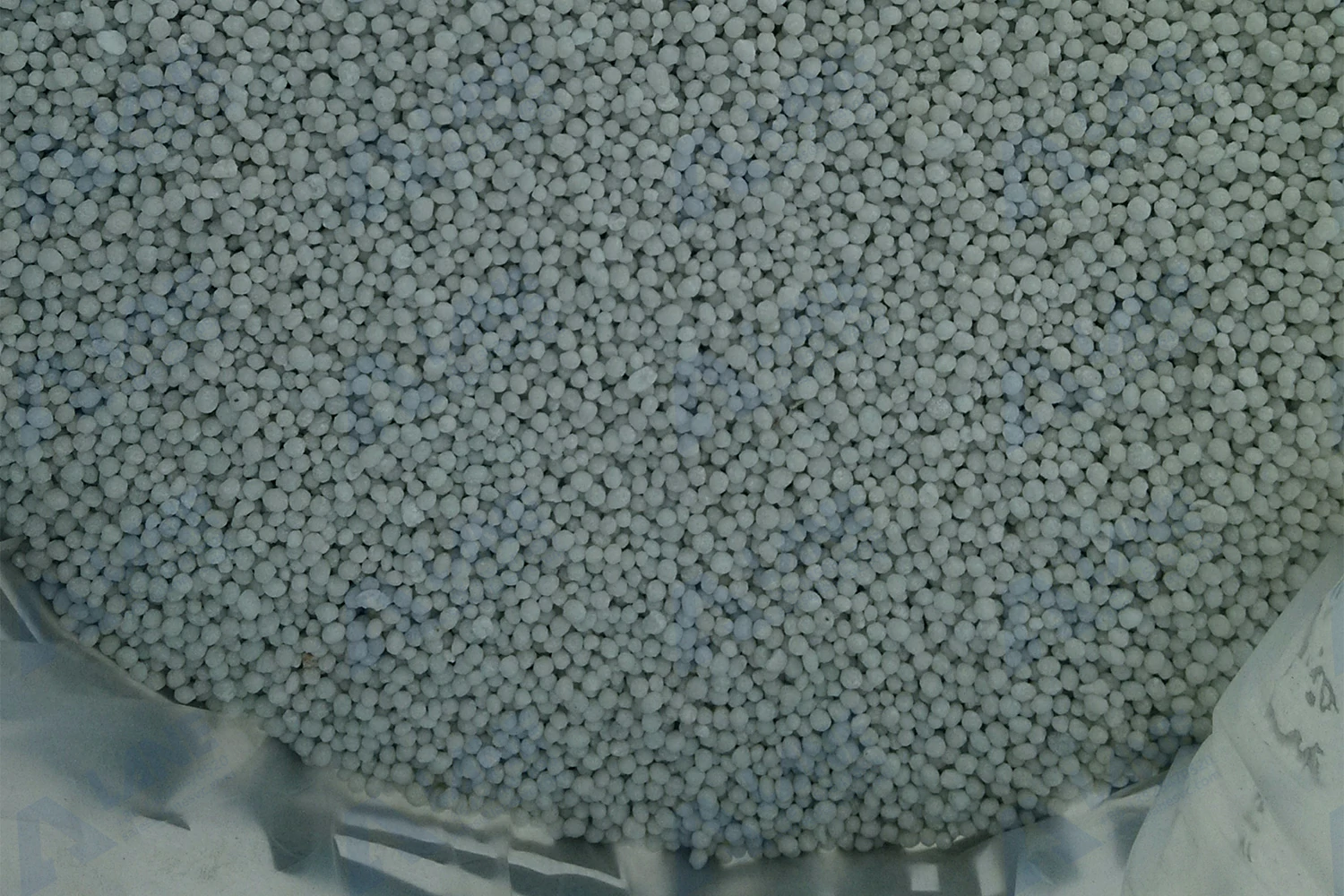

The machine is mainly used for compound fertilizer production drying a certain temperature and particle size of fertilizer, its characteristics are as follows:

1) Small investment, quick effect, good economic benefit, reliable performance;

2) Small power, no emission of three wastes, stable operation, convenient maintenance, reasonable process layout, advanced technology and low production cost.

3) The distribution and angle of the lifting plate are reasonably designed, with reliable appearance and performance, thus the heat energy utilization rate is high, the drying is even, and the number of times to clean up the materials is less.

| Model | Capacity(tph) | Drum Size(mm) | Rotation Speed(r/min) | Steel Plate Thickness(mm) | Lift Plate Thickness(mm) | Power(kw) |

| LARD0808 | 1-2 | Φ800*8000 | 5 | 8 | 4 | 5.5 |

| LARD1010 | 2-3 | Φ1000*10000 | 5 | 10 | 6 | 5.5 |

| LARD1212 | 3-5 | Φ1200*12000 | 5 | 10 | 6 | 7.5 |

| LARD1515 | 5-8 | Φ1500*15000 | 5 | 12 | 6 | 15 |

| LARD1616 | 8-12 | Φ1600*16000 | 5 | 12 | 6 | 18.5 |

| LARD1818 | 12-15 | Φ1800*18000 | 4 | 14 | 6 | 22 |

| LARD2020 | 20-25 | Φ2000*20000 | 4 | 14 | 6 | 37 |

| LARD2222 | 25-30 | Φ2200*22000 | 4 | 16 | 6 | 37 |

| LARD2424 | 30-35 | Φ2400*24000 | 4 | 16 | 6 | 45 |

| LARD2626 | 35-40 | Φ2600*26000 | 3 | 18 | 6 | 55 |

| LARD2828 | 40-45 | Φ2800*28000 | 3 | 18 | 6 | 75 |

| LARD3028 | 45-50 | Φ3000*28500 | 3 | 18 | 6 | 90 |

1) Bracket part: the machine bracket part of the medium-carbon steel plate, channel steel welded into, in addition to the more important is fixed in the bracket on the wheel, deliberately selected high-quality anticorrosion, wear-resistant materials, greatly improving the service life of the machine.

2) Transmission part: the transmission frame is welded with high quality channel steel, the motor drives the belt pulley, triangle belt, reducer transmission to the spindle, so that the body work, in which the transmission reducer and the spindle part of the work, using nylon pin coupler to bite the transmission drive.

3) Large gear ring: fixed in the body, and transmission pinion gear, phase to drive the body work, the use of cutting-edge wear-resistant materials, so that the service life of the machine longer.

4) Rolling belt: fixed on both sides of the body to support the whole body.

5) Body part: welded with high quality medium carbon steel plate, built-in lifting plate adopts high quality wear-resistant material.

1) The belt and pulley are driven by the main motor, and driven to the main shaft through the speed reducer, and work in the opposite direction through the folio gear installed on the main shaft and the large gear ring fixed on the body.

2) The material is added from the feeding end, and the hot air produced by the hot air furnace (used with the machine) inside the cylinder body enters into the inside of the cylinder body under the gravitational force of the fan.

3) The lifting plate installed inside the cylinder body constantly turns the material up, so as to achieve the purpose of drying evenly. The dried material flows out from the discharge port.

4) With the continuous rotation of the motor, the materials continue to enter the mass production (Note: the rotary drum dryer is used in conjunction with the rotary cooler, due to the high temperature of the dried particles, is not conducive to storage, must be cooled before storage).

1) High efficiency and energy saving: the rotary drum dryer adopts heat convection for drying, with high heat utilization and low heat loss. At the same time, the flue gas can be recycled after treatment, which reduces the consumption of energy and lowers the production cost.

2) Good drying effect: The rotary drum dryer adopts unique rotary drum design and fluidization technology, which can evenly distribute the fertilizer raw materials, so that they can get sufficient heat and air circulation in the drying process, thus realizing fast and even drying effect.

3) Strong adaptability: the rotary drum dryer can adapt to different kinds and humidity of fertilizer raw materials. By adjusting the rotating speed of rotary drum, feeding speed and hot air temperature, it can meet the drying demand of different raw materials, which improves the flexibility and adaptability of the equipment.

4) Easy to operate: The rotary drum dryer adopts advanced automatic control system, which is easy and convenient to operate. By setting the drying temperature and time and other parameters, automatic operation can be realized, saving labor cost.

5) After drying granules with high humidity, the rotary dryer can greatly enhance the storage time of fertilizer and prevent nutrient loss.