The chain crusher is one of the core pieces of equipment in a compound fertilizer production line, specifically designed for crushing block-shaped fertilizers (such as calcium phosphate, heavy calcium, and nitric acid phosphate fertilizers) and materials of medium hardness.

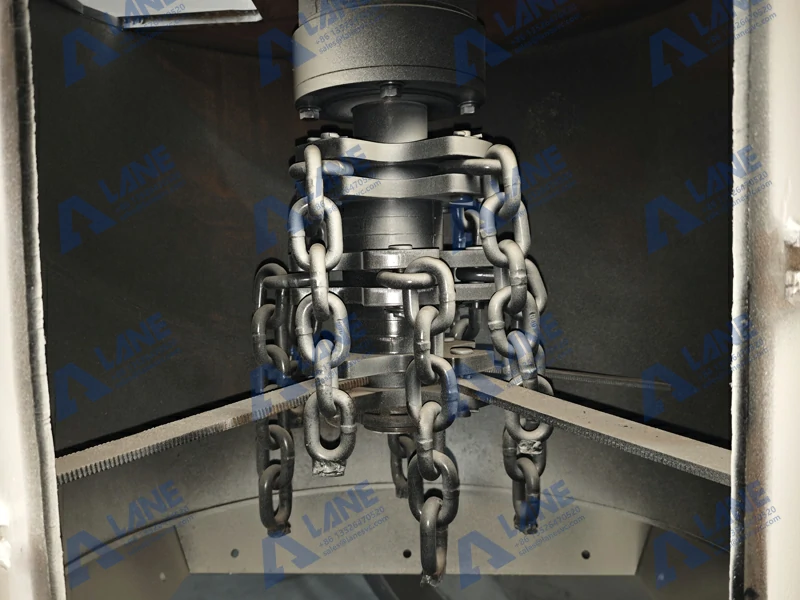

The chain crusher employs high-speed rotating wear-resistant alloy chains to impact-crush materials, featuring uniform crushing, minimal wall adhesion, and compatibility with high-moisture materials (moisture content up to 50%).

In addition to the compound fertilizer industry, it is widely applied in chemical, construction materials, and mining sectors, particularly suited for processing high-moisture or corrosive materials such as ores, organic fertilizer raw materials, and livestock manure.

| Model | LACC50/LP45 | LACC60/LP56 | LACC100/LP1012 |

| Center distance (mm) | 400 | 600 | 1000 |

| Feed particle size (mm) | <100 | <100 | <120 |

| Discharge particle size (mm) | ≤3 (70% to 90%) | ≤3 (70% to 90%) | ≤1(80%) |

| Production capacity (t/h) | 5~9 | 6~10 | 20~30 |

| Motor power (kW) | 7.5×2 | 11×2 | 45×2 |

| Applicable materials | Compound fertilizer blocks, wet sand | Organic compost, ore | High-hardness ore, phosphate rock |

Rotor System:

Machine Body and Protection:

Drive system: Dual motor belt drive ensures high torque output.

Material enters the chain crusher through the feed port and is directed into the dual rotor zone. The high-speed rotating chains subject the material to multiple impacts:

High Adaptability:

Energy Efficiency and Maintenance:

Flexible particle size control: Adjusting the number of chains allows adaptation to coarse crushing (≤3mm) or fine crushing (≤1mm) requirements.

Technical Improvements

Vertical chain hammer composite design: Combines chain pre-crushing with hammer plate fine crushing, achieving a particle size of 50 mesh (0.3mm), suitable for ultra-fine fertilizer or mineral processing.

Engineering integration capabilities:

Provides integrated solutions for crushing, conveying, and screening, such as spiral closed conveyors, to achieve dust-free production and meet environmental protection requirements.

Customized design:

Customizes lining materials (rubber/polypropylene) and chain alloy grades based on material characteristics (such as corrosiveness and humidity). Customizes motor power, voltage, etc. based on local factory conditions.

Technical Support:

We offer R&D services, including process parameter optimization and equipment commissioning services, to ensure production capacity and particle size meet standards.

The chain crusher, with its dual-rotor impact crushing principle and highly adaptable design, has become an indispensable piece of equipment in the compound fertilizer and mineral processing industries.

Lane Machinery addresses challenges in fertilizer production, such as high-moisture material adhesion and uneven particle size, through engineering integration, intelligent control, and customized services. This makes it particularly suitable for companies with stringent environmental and energy efficiency requirements.

For customers planning to build new or upgrade existing fertilizer production lines, the technical reliability and long-term cost advantages of the Lane chain-type crusher are significant, making it a priority for procurement.

If you are looking for a chain crusher, please contact us, and we will immediately send you a quote and equipment operation video.