BB fertilizer is a kind of compound fertilizer which is made by mixing many kinds of single-element fertilizers in proportion.

BB fertilizer production line mainly consists of weighing equipment, mixing equipment, packaging equipment and so on, which can be adjusted and expanded according to different needs.BB fertilizer production line can mix different kinds and proportions of fertilizer raw materials accurately and make composite fertilizers in the form of granules or pellets.

BB fertilizer ingredients include a variety of nutrients such as nitrogen, phosphorus, and potassium, as well as other auxiliary ingredients. Specific ingredients include, but are not limited to, the following:

Urea: a source of nitrogen, containing high purity nitrogen that is easily dissolved to quickly provide the nitrogen nutrients needed by plants.

Potassium Dihydrogen Phosphate (Dipotassium Hydrogen Phosphate): Phosphorus and Potassium source, rich in phosphorus and potassium, which improves plant development and resistance performance.

Potassium Sulphate: Potassium source, rich in potassium, provides essential potassium to promote plant growth and fruiting.

Ammonium Nitrate: Nitrogen source, containing high concentration of nitrogen, which can be quickly absorbed and utilized by plants.

Potassium Nitrate: Nitrogen and potassium source, containing nitrate nitrogen and potassium elements, which can promote plant growth and disease resistance.

Calcium Nitrate: Nitrogen and calcium source, containing nitrate nitrogen and calcium elements, which can provide the nutrients needed by plants and regulate the acid-base balance.

Sodium nitrate: nitrogen source, containing nitrate nitrogen, can be fully absorbed and utilized by plants.

The above are common BB fertilizer raw materials, according to different product formulations and needs, you can also add other trace elements and auxiliary ingredients, such as amino acids, organic matter, microbial fungicides, etc., in order to further improve the effect of fertilizer and nutritional balance!

| Product Name | Machine Parameters | Speed | ||

| Dynamic Batching System | PVC drive belt: width 0.5m, length 2m | 1.1-2.2KW | SBD series reducer | 1450r/min |

| Bucket Elevator | Maximum feeding size: 25-55cm | Hopper width:160-400mm | Bucket type Q/H: 12/22m*3/h | 1.4m/h |

| BB Fetilizer Mixer | 500L | 7.5KW | 380V or custom-made | 1450r/min |

| Ton Charter Aircraft | 10-40 Bag/H | 5.5KW | 1600*1600*2800mm | AC380V |

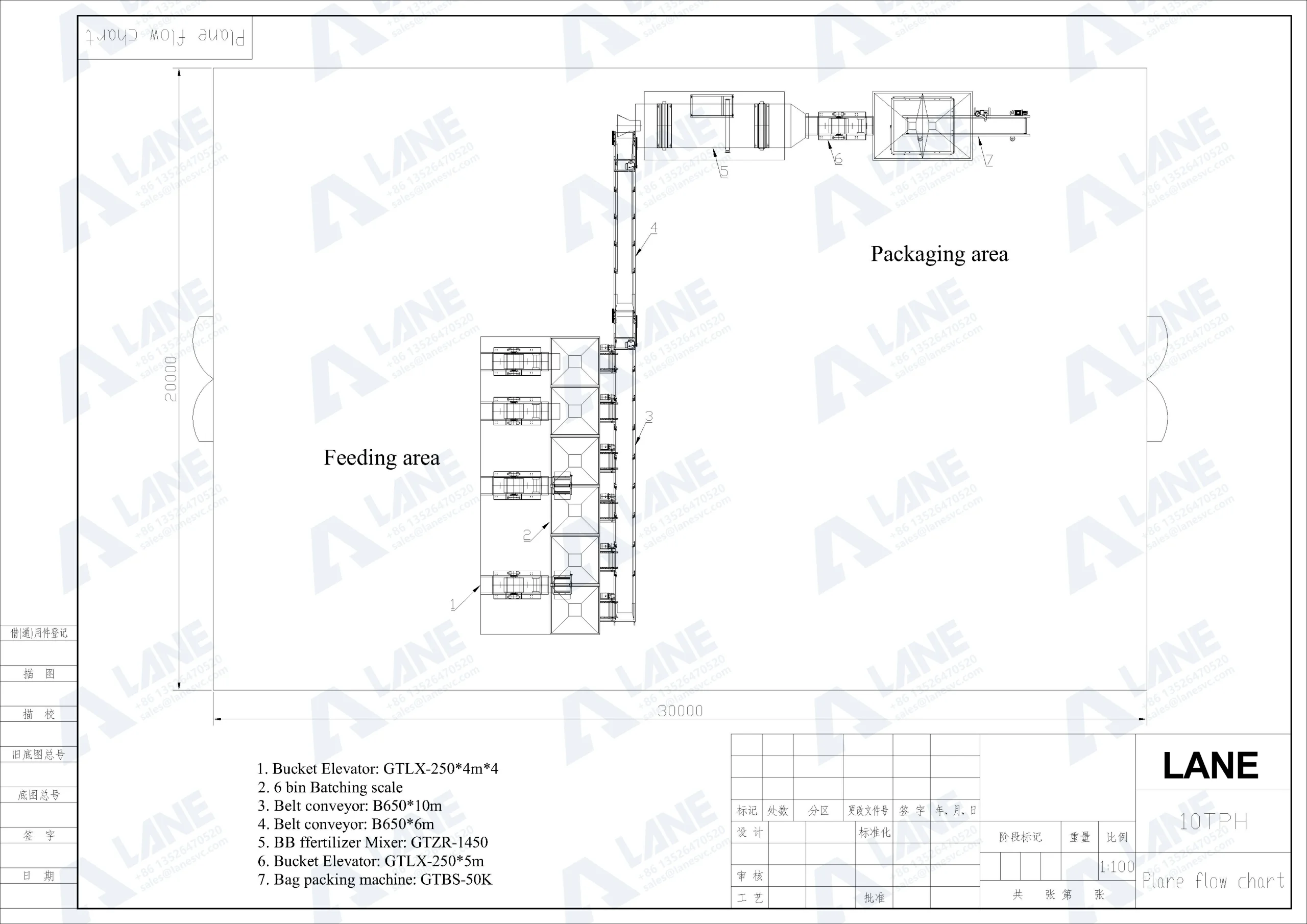

BB fertilizer production line contains conventional equipment: bucket elevator, dynamic batching machine, rotary drum mixer, automatic packaging machine, belt machine and so on.

1) Batching: Nitrogen, phosphorus, potassium, filler and other raw materials are transported to the relevant bins, weighed by the automatic measuring device, and sent to the pre-mixer.

2) Mixing: conveyed to the horizontal BB fertilizer mixer (intermittent, continuous), granular materials with the help of horizontal BB fertilizer mixer rotating to form irregular material curtains, mixing uniform granular materials along the mixer tilt direction of the slow rolling to the outlet.

3) Packing: The mixed material is conveyed to the finished product packing scale for packing and storage.

Efficient production: BB fertilizer production line is able to realize automated production, reduce labor cost and improve production efficiency. Through automated operation, it can realize continuous and stable production and improve the quality and output of products.

Precise proportioning: BB fertilizer production line is equipped with advanced dynamic batching system, which is able to control the speed of raw material placement in real time through the console, and precisely adjust the proportion of fertilizers according to the needs of crops to ensure that the nutrients of fertilizers are reasonably and balanced supplied to the plants, and to improve the effect of fertilizer application.

Strong flexibility: BB fertilizer production line can quickly adjust the product formula and specifications according to different user needs and market changes, to meet the needs of different crops and soils, and provide personalized fertilizer solutions.

Resource saving: BB fertilizer production line adopts advanced production process and technology, which can minimize the waste of raw materials and energy consumption, and realize the effective use of resources and environmental protection