1) Additives are not necessary, the most important ingredient in making cat litter is bentonite clay.

2) The content of powder additives is usually only 20% at most. Therefore, the content of bentonite is about 80%.

3) To make 200 bags of 5 kg (1 ton) of cat litter, you need about 800 kg of bentonite powder.

4) The powder additive can be 10% wood ash and 10% diatomaceous earth.

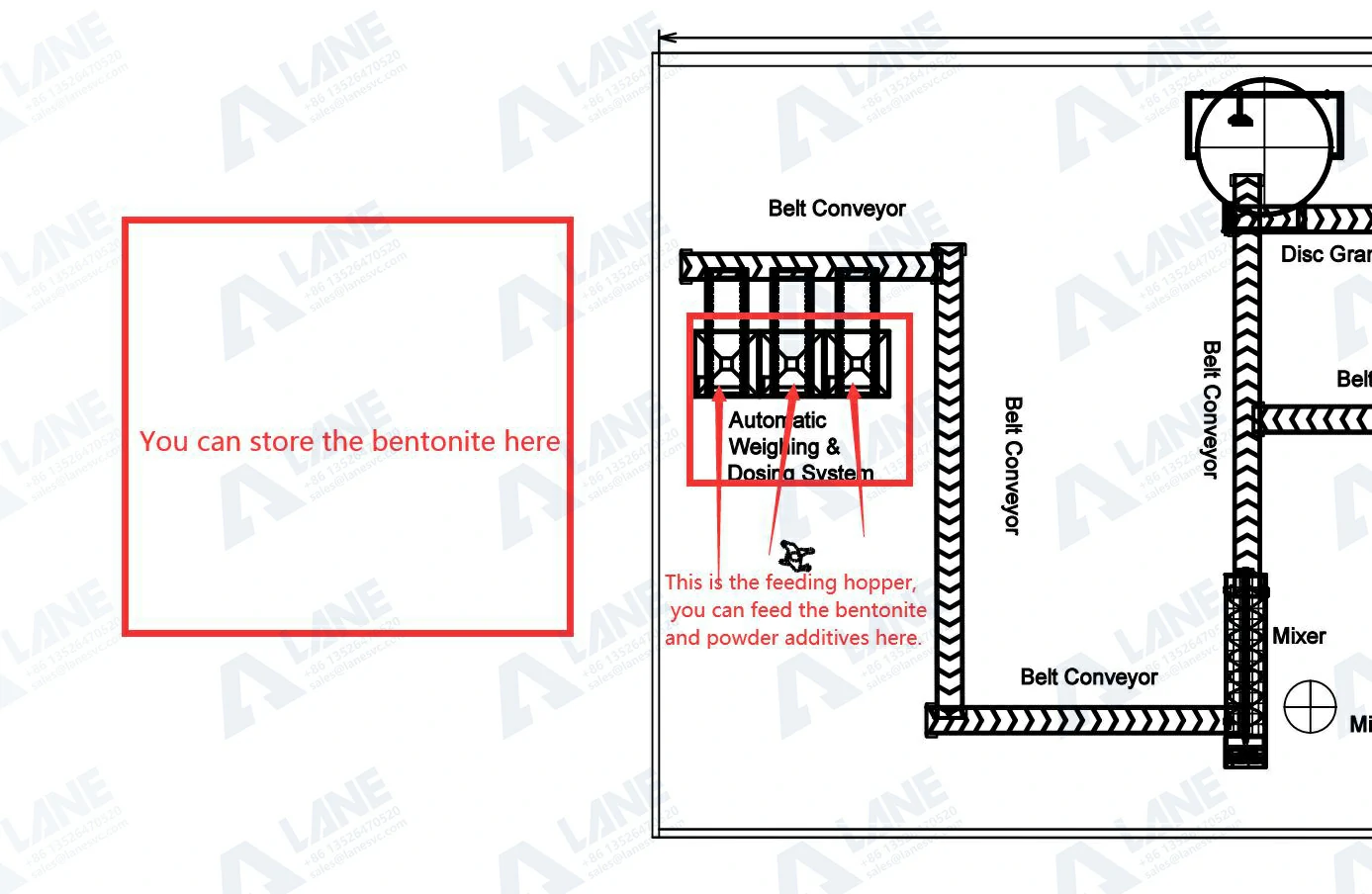

Bentonite and powder additives are prepared by a three-compartment automatic weighing and dosing system in a certain proportion.

You have a production capacity of 1 t/h and an input of 800 kg/h of bentonite powder. Therefore, if you run this line 8 hours a day, you will need to prepare approximately 6.5 tons of bentonite per day, or 200 tons of bentonite per month. The shelf life of bentonite is typically six months. Depending on production, bentonite material can be stored for 3-6 months (600 to 1200 tons).

You can store bentonite in a dry, sun-protected room that can be built on the side of the feeding area.

1) Regarding bentonite acidification and sodium reduction, it is a matter of raw material treatment, no need to do it yourself.

2) Suggest that you directly buy sodium bentonite, sodium bentonite is a sodium chemical reaction after the water absorption of raw materials, powder does not need to be treated.

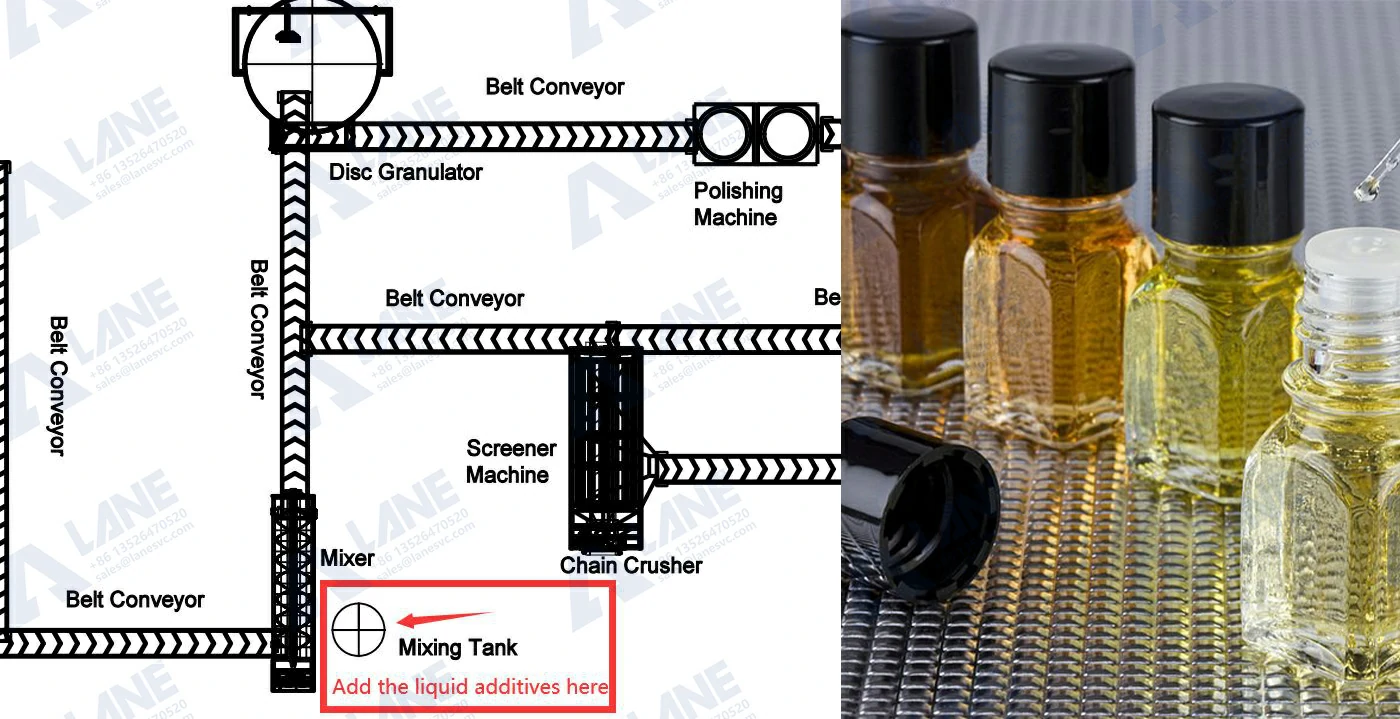

For liquid additives, you just need to add some water. If desired, you can also add some liquid flavor. Flavors can be added in small amounts, as little as 1% of the water. You can store and add liquids in the mixing tank.

Cat litter sold on the market often has some colored pellets mixed in, which is really just for aesthetic purposes and nothing else. And these pellets are not in large quantities, so there is no need to invest the extra expense to mass produce them.

Most manufacturers choose to use a small pelletizer to spray the processed white natural pellets with color and then spray them into normal pellets. This would be the most economical and efficient method.

Usually the scent is liquid and there are many different flavors that you can easily buy on the market and you just need to add a little, and mix water with it in a 100:1 ratio. Store it in a mixing tank and we have pipes that are connected to a spraying device in the mixer. Spray it on the powder and mix evenly.

Yes, we will provide. The packaging machine can be adjusted and customized by your need. You just need tell me your bag size.

Our small scale cat litter production line equipment adopts the most advanced technology and process with several advantages to make your production process more efficient and smooth.

In addition, our equipment is flexible and customizable. We understand that every customer’s needs are different, so we offer a wide selection of equipment in a variety of sizes and configurations to meet your specific needs. We also offer customized design and manufacturing services, tailored to your requirements to ensure that the equipment is perfectly suited to your production needs.

With our small scale cat litter production line equipment, you can invest with confidence in a reliable solution that will enhance your productivity and competitiveness. We are committed to providing you with the best quality equipment and services, and growing and succeeding with you!