Sulfur coated urea (SCU for short) is a kind of compound fertilizer with high nitrogen fertilizer efficiency, which wraps urea and sulfur together, which can effectively reduce the volatilization loss of nitrogen fertilizer and improve the nitrogen uptake by crops.

The sulfur coated urea production line mainly includes the processes of urea granule wrapping, sulfur treatment and drying, etc. Urea and sulfur are physically wrapped through specialized equipment to form fertilizers with slow-release characteristics.

| Equipment Name | Main Function | Technical Parameters | Remarks |

|---|---|---|---|

| Urea Granulator | Granulating urea solution or pellets | – Capacity: 1-30 tons/hour – Granule size: 2-5mm – Motor power: 45-200 kW |

Customized based on capacity needs |

| Sulfur Melting Furnace | Melting solid sulfur | – Melting temperature: 150-180°C – Melting capacity: 1-20 tons/hour |

Temperature control system for stable melting |

| Mixer | Mixing urea granules and molten sulfur | – Mixing capacity: 2-10 tons/batch – Mixing time: 10-15 minutes |

Equipped with mixing device for uniformity |

| Coating Machine | Coating molten sulfur onto urea granules | – Coating capacity: 1-20 tons/hour – Temperature range: 50-70°C |

Controls coating thickness for quality assurance |

| Cooling Machine | Cooling the coated urea granules | – Cooling temperature: 30-50°C – Cooling time: 15-30 minutes |

Lowers the temperature and stabilizes the coating layer |

| Dryer | Removing moisture from urea granules | – Processing capacity: 2-15 tons/hour – Temperature: 50-70°C |

Prevents granule adhesion and ensures dryness |

| Sieving Machine | Sieving out unqualified granules | – Sieving accuracy: ≥98% – Sieve mesh size: 2-6mm |

Adjustable mesh size to suit different granule needs |

| Automatic Packing Machine | Packaging the finished sulfur-coated urea | – Packaging capacity: 10-50 kg/bag – Production speed: 20-50 bags/min |

Increases packaging efficiency and reduces labor costs |

Key process and equipment of sulfur coated urea production line

1. Raw material preparation

Urea: as a nitrogen source, it is mainly produced through the reaction between ammonia and carbon dioxide.

Sulfur: as a coating substance, sulfur plays a slow release role in the production of sulfur coated urea, usually by melting and coating with urea particles.

Excipients: other additives (e.g. trace elements, regulators, etc.) may be added according to the needs of the product.

2. Production process

Preparation of urea granules

Equipment: Granulator

Urea granules are formed using urea synthesis liquid or solution through a granulator.

The granulator can use disk, drum or airflow granulation technology, urea granules are formed under certain conditions with a standard particle size.

Sulphur melting and mixing

Equipment: Sulphur melting furnace, mixer

Sulfur needs to be melted through the melting furnace first to form liquid sulfur.

After melting, the sulfur and urea granules are evenly mixed by the mixer.

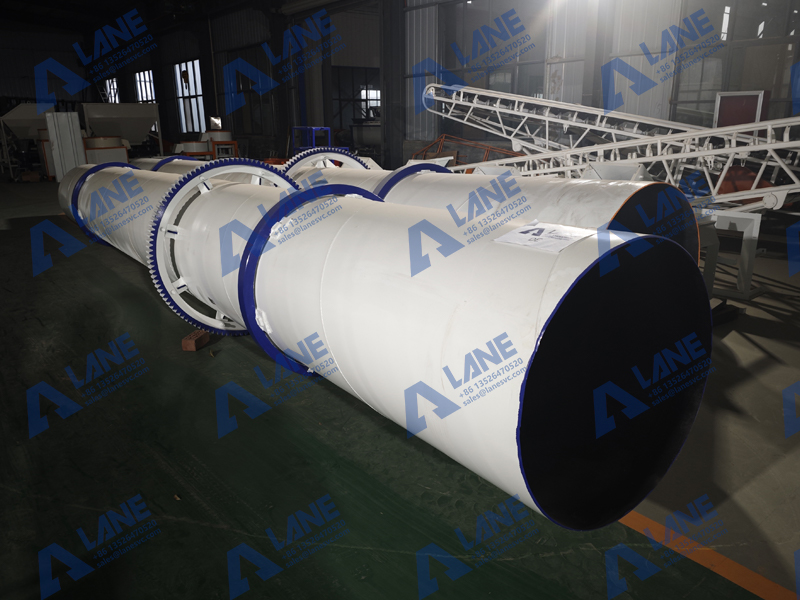

Coating process

Equipment: Coating Machine (Coating Machine)

In the cladding machine, urea granules and molten sulfur undergo cladding process to ensure that the sulfur completely covers the surface of urea granules.

The quality of the sulfur-coated urea and the thickness of the coating are controlled by adjusting the temperature and coating time.

Cooling and Curing

Equipment: Cooling machine

After coating, the urea granules need to be cooled down by the cooling machine, and then cooled down to room temperature to ensure the stability of the coating layer.

Drying and Sieving

Equipment: dryer, sieving machine

After cooling, the urea granules need to enter the dryer to remove excess water and prevent adhesion between the granules.

The sieving machine sifts the pellets according to size to ensure the uniformity of the finished pellets.

Packaging and Storage

Equipment: automatic packaging machine

After the finished sulfur-packed urea granules are sieved, they enter the automatic packing machine for measuring and packing, and are finally packed into bags for easy transportation and storage.

Slow down the release of nitrogen fertilizer: Sulfur coating layer can slowly release the nitrogen in urea, which improves the holding period and use efficiency of fertilizer.

Reduce nitrogen loss: Sulfur can effectively prevent the nitrogen in urea from volatilizing, thus reducing the loss of nitrogen and improving the utilization of nitrogen by crops.

Enhance soil health: Sulfur acts as a soil acidifier, which can effectively adjust the pH of the soil and improve the soil environment.

Environmentally friendly: sulfur coated urea production line reduces the volatilization of nitrogen oxides during application, making it friendlier to the environment.

The equipment and process design of the sulfur coated urea production line is crucial for product quality, production efficiency and cost control. By optimizing the production line, the quality and market competitiveness of the fertilizer can be improved. In the growing development of green agriculture today, sulfur coated urea production line is undoubtedly a worthwhile investment direction. If you have related needs, welcome to contact us, we will provide you with the most professional equipment and technical support.