Experimental purpose: To explore the best granulation conditions and methods by studying the granulation process of gypsum powder, and to provide reference for the production of gypsum fertilizer.

Raw material: Calcined Gypsum powder

Raw material Moisture:2-3%

Raw material form: powder

Raw material Powder Mesh:80-100m

Calcined Gypsum powder: 20kg

Water prepare:2.95kg

Mixing process:0.8kg

Remaining water: 1.15kg

Finished pellet weight: 9.45kg(Select a portion)

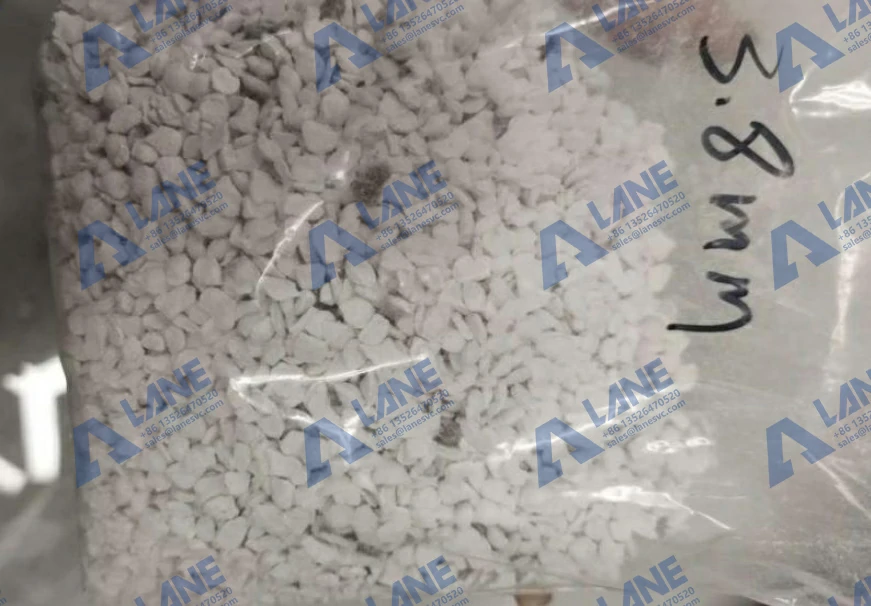

Finished particle shape: spherical

Finished pellet Include: 6mm=1.95kg (accounted for 20.6%)

5mm=1.60kg(accounted for 16.9%)

4mm=3.50kg(accounted for 37%)

3mm=1.80kg(accounted for 19%)

2mm=0.60kg(accounted for 6%)

Raw material: Calcined Gypsum powder 20kg

Added water: 2.95kg (Adding 0.8kg during the mixing process, adding 0.8 during granulation process)

Finished pellet weight: 9.45kg (Select a portion)

Ball rate: 99.5%

Date:2023/11/20

Calcined Gypsum powder: 73.6kg

Water prepare:16.6kg

Mixing process:8.4kg

Remaining water:8.2kg

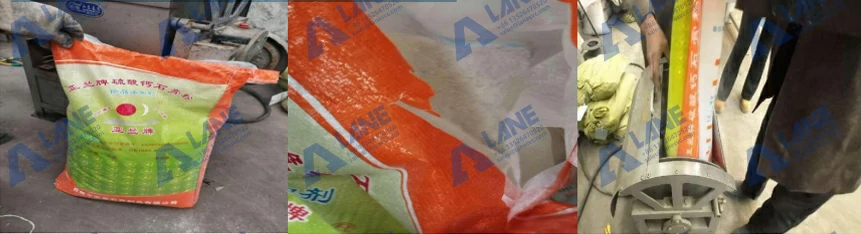

3. Stirring Pin granulator –experiment procedure

Finished pellet weight: 20.6kg(Select a portion)

Finished particle shape: spherical

Finished pellet Include: 6mm=2.10kg (accounted for 10.1%)

5mm=3.30kg(accounted for 16%)

4mm=5.50kg(accounted for 26.6%)

3mm=4.31kg(accounted for 20.9%) 2mm=2.3kg(accounted for 11.1%)

Raw material: Calcined Gypsum powder 73.6kg

Added water: 8.4kg (Just adding 8.4kg during the mixing process)

Finished pellet weight:20.6kg (Select a portion)

Ball rate: 85%

Calcined Gypsum powder: 13.25kg

The experiment failed due to the strong viscosity of the raw materials.

The raw material adheres to the equipment roller skin and is difficult to form.