Organic Fertilizer Production Line is a series of fertilizer machine that uses fermentation and composting technology to convert organic waste into high quality and easy-to-store organic fertilizer granules.

The production line is mainly composed of raw material treatment system, fermentation and composting system, granulation system, drying system and packaging system.

1) Poultry and livestock manure: pig manure, chicken manure, cow and sheep manure, horse manure, pigeon manure and other livestock manure.

2) Agricultural waste: straw, soybean meal, cotton meal, mushroom slag, marsh dregs, mushroom dregs, etc.

3) Industrial waste: wine dregs, vinegar dregs, cassava dregs, sugar dregs, furfural dregs, etc.

4) Domestic waste: food waste, etc.

Our customized organic fertilizer production line can be close to your needs, according to the raw materials you provide and output requirements for you to design the most affordable production line equipment, you can ask us for relevant information, welcome to get a quote!

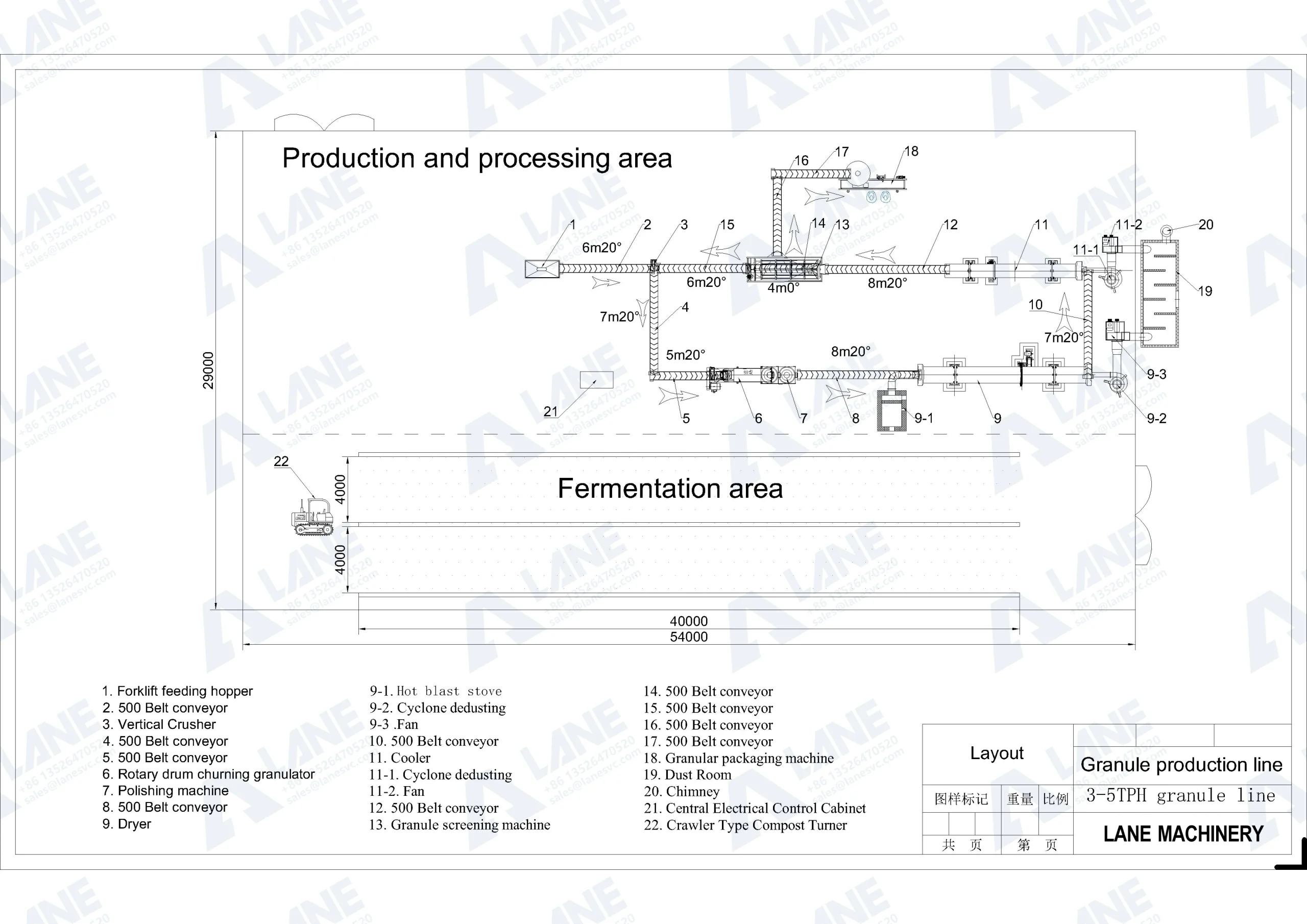

The machines in the organic fertilizer production line contain compost turner, forklift feeder, crusher, new organic fertilizer granulator, polishing machine, drying and cooling machine, screening machine, packing machine and cyclone dust removal.

The following is the parameter list of conventional equipment for organic fertilizer production line, the specific model and output can be customized according to your needs.

| Product Name | Model | Yield | Detail | Speed | Power |

| Crawler Compost Turner | LALG-2500 | 400-1500m*3/h | Stacking height 600mm-1500mm | 5-10m/min | 36-170 horsepower |

| Forklift Feeding Hopper | LAH-1.5-3 | Silo size: 1-4 meters | 2250mm*1050mm*1590mm | 1450r/min | 2.2-3KW |

| Vertical Crucher | LAC-60V | 1-12t/h | ZQ series reducer | 1450r/min | 7.5-37KW |

| Organic Fertilizer Granulator | LAZJ-1000 | 1-8t/h | ZY series reducer | 1450r/min | 7.5-11KW |

| Polishing Machine | LAP2-800 | 2-10t/h | Double bearing | 1450r/min | 3-7.5KW |

| Rotary Drum Drying Machine | LARD:1.2-12 | 1-25t/h | ZQ series reducer | 1450r/min | 5.5-22KW |

| Cooling Machine | LARC-1.0-10 | 1-20t/h | ZQ series reducer | 1450r/min | 5.5-22KW |

| Rotary Screen Machine | LAS-1240 | 1-23t/h | ZQ series reducer | 1450r/min | 3-7.5KW |

| Pellet Packing Machine | LAB-50K | 4-30 bags/minute | Packaging specification: 20-50kg | 4-6 bags/min | 50Hz/60Hz/220V/380V |

1) Fermentation: the raw materials are fermented according to a certain proportion, and the materials are composted and turned in the process of fermentation, so that the materials can be fully and evenly fermented.

2) Crushing: the raw materials after fermentation will be crushed, and the crushed raw materials will reach the required granularity before granulation.

3) Screening: Part of the particle fineness of the material is relatively large for screening, back to the second crushing to reach the standard fineness.

4) Mixing: the crushed raw materials to join the corresponding auxiliary materials for mixing, to improve the overall uniformity of fertilizer particles fertilizer content.

5) Granulation: stirred raw materials into the organic fertilizer granulator for granulation (granulator has a variety of models, according to the production process to choose the right organic fertilizer granulator).

6) Drying: granulator made of organic fertilizer particles sent to the dryer to dry the particles contained in the moisture, increase particle strength.

7) Cooling: after drying the fertilizer particles temperature is too high, easy to caking, cooling treatment is convenient for preservation and transportation.

8) Screening: the cooled particles are screened, unqualified particles return to the crusher for crushing, re-pelletizing, sieving out the qualified products, into the next process.

9) Coating: Qualified organic fertilizer particles are coated to prevent the particles from clumping, slow down the release of fertilizer and increase the brightness and roundness of the particles.

10) Packaging: After filming the particles become finished organic fertilizer particles, use automatic packaging machine to pack them into bags, placed in a dry and ventilated place for storage.

Our organic fertilizer production line is fully designed to include all production processes from raw materials to finished pellets.

It can be adjusted according to customer’s needs to meet of customer’s requirements, and strive for the maximum benefit of organic fertilizer production line under customer’s specific conditions.