Disc granulator is a big pan-shaped machine set on top of a hard base plate. You can use it to make round pellets of assorted materials. Together with other fertilizer making machines, you can form a highly efficient fertilizer production line with a disc fertilizer compost granulator. Disc granulator is resistant and has a long service life. resistant and has a long service life,which makes it popular.

Disc granulator has a wide range of applications, not only can be used in organic fertilizer production line, compound fertilizer production line and other fertilizer production line, but also can make cat litter and other material particles.

As an experienced fertilizer machinery manufacturer, we offer a vast range of models and component materials for customers to choose from, striving to meet all their expectations!

| Model | Capacity(tph) | Size(mm) | Power(kw) | Rotation Speed(rpm) | Pan Diameter(mm) | Tilt Angle(°) |

| LAZD-500 | 0.05-0.1 | 650*600*800 | 0.75 | 32 | 500 | 35-55 |

| LAZD-1000 | 0.1-0.2 | 1800*1200*1600 | 3 | 25 | 1000 | 35-55 |

| LAZD-1200 | 0.2-0.4 | 2000*1400*1950 | 3 | 22 | 1200 | 35-55 |

| LAZD-1500 | 0.4-0.6 | 2200*1800*2050 | 4 | 20 | 1500 | 35-55 |

| LAZD-1800 | 0.6-0.8 | 2600*2000*2450 | 5.5 | 16 | 1800 | 35-55 |

| LAZD-2000 | 0.8-1 | 2900*2100*2750 | 7.5 | 16 | 2000 | 35-55 |

| LAZD-2200 | 1-1.5 | 2530*2100*2800 | 7.5 | 18 | 2200 | 40-50 |

| LAZD-2500 | 1.5-2 | 2630*2600*2800 | 7.5 | 16.2 | 2500 | 40-50 |

| LAZD-2800 | 2-3 | 2850*3020*3110 | 7.5 | 14.2 | 2800 | 40-50 |

| LAZD-3200 | 3-4 | 3600*3030*3310 | 11 | 13.5 | 3200 | 40-50 |

| LAZD-4000 | 4-5 | 4500*3300*4000 | 15 | 12.3 | 4000 | 45 |

| LAZD-4500 | 5-6 | 5100*3700*4400 | 22 | 10 | 4500 | 45 |

| LAZD-6000 | 6-10 | 6400*5000*6000 | 75 | 8.9 | 6000 | 45 |

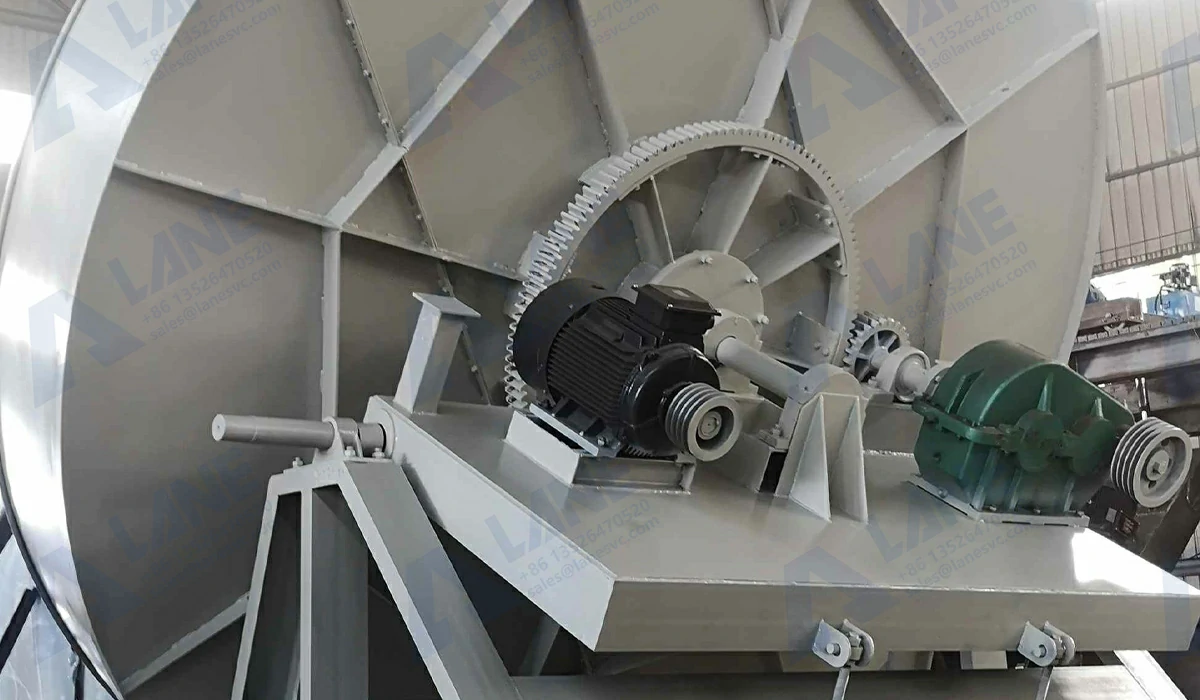

1) Firstly, the main motor drives the belt pulley and belt, and drives the pinion gear through the speed reducer, and the pinion gear and the big gear fixed on the bottom of the disc are mutual gears, and work in the opposite direction.

2) The big gear is mounted on the main shaft fixed on the adjusting plate of the frame through special and reasonable design to support the work of the whole pelletizing plate (this machine is used together with spraying machine).

3) After the material enters into the pelletizing disc, the continuous rotation of the pelletizing disk and the spraying device will make the material uniformly stick and cause the round ball-shaped particles.

4) The upper part of the granulating disc of this machine is designed with an automatic clearing device to prevent the material from sticking to the wall, which greatly improves the service life of this machine.

5) With the continuous rotation of the motor and the continuous entry of materials, the machine can realize mass production and meet the needs of users.

1) The angle of granulating disk adopts arc structure, the granulation rate can be more than 93%.

2) The speed reducer and motor adopt flexible belt transmission, which can start smoothly, slow down the impact and improve the service life of the equipment.

3) The bottom of granulating disc is strengthened by several radial steel plates, which is durable and never deformed.

4) Thickened, aggravated, strong base design, no need to fix the foot bolt, smooth operation.

5) The main gear of the granulator adopts high-frequency burst fire, which doubles the service life.

6) The machine has the advantages of even granulation, high rate of ball formation, stable operation, durable equipment, long service life, etc.

7) The disc granulator is highly praised by the users, and is the ideal product for the majority of users to choose.

1) The corner part of the pelletizing disk adopts rounded corner design, which effectively solves the problem of material sticking and piling up and can’t be cleaned up.

2) Increase the receiving port, solving the problem of material spilling out in the process of rotation.