A drum composting machine, also known as a rotary drum composter, is designed to convert various types of organic waste into nutrient-rich organic fertilizer. This machine is efficient, automated, and environmentally friendly, making it ideal for modern organic fertilizer production.

The drum composting machine can process a wide range of organic solid wastes, including:

– Kitchen waste

– Food waste

– Sludge

– Garden waste

– Farm manure

– Plant straw

– Food fungus scraps

– Fruit and vegetable wastes

– Medicinal dregs

– Animal processing wastes

– Biogas residue

The capacity of the drum composting machine depends on the amount of waste generated by your industry. The smallest bioreactor has a capacity of 10 cubic meters, while the largest can handle up to 127 cubic meters.

| Model | Drum Volume(m³) | Loading volume (m ³) | Daily processing capacity (m ³) | Daily production (t) | Installed power (Kw) | Dimensions (m) |

| LAHT-2800 | 200 | 140 | 46 | 22 | 11*2 | 28*3*3 |

| LAHT-2400 | 170 | 120 | 40 | 20 | 7.5*2 | 24*3*3 |

| LAHT-2000 | 141 | 99 | 33 | 46 | 5.5*2 | 20*3*3 |

| LAHT-1800 | 127 | 89 | 30 | 14 | 4.5*2 | 18*3*3 |

| LAHT-1200 | 85 | 60 | 20 | 10 | 4*2 | 12*3*3 |

| LAHT-1000 | 70 | 50 | 15 | 8 | 2.2*2 | 10*3*3 |

| LAHT-800 | 25 | 18 | 5 | 3 | 1.1*2 | 8*2*2 |

| LAHT-600 | 18 | 13 | 3 | 2 | 0.75*2 | 6*2*2 |

| LAHT-500 | 10 | 7 | 1.5 | 1 | 0.55*2 | 6*1.5*1.5 |

Compost Readiness

Upon leaving the bioreactor, the compost is sanitized, heated, and humidified. It is recommended to allow the compost to stabilize (age) for one month to achieve optimal conditions suitable for crops and plants.

Leachate Management

To prevent leachate production, the bioreactor requires the waste to have a humidity level between 60% and 65%. This condition helps avoid nutrient loss and enriches the final compost.

Customized Compost Characteristics

The final compost quality depends on the type of waste being treated. Specific characteristics are achieved through the initial mixture of waste, which is conditioned before starting the process.

Compost Temperature

The compost exits the bioreactor at approximately 55°C and then undergoes further processing.

Impurity Removal

While minimal contamination with non-organic materials is possible, it is essential to separate residues at the source or before introducing them into the mixer to avoid decomposition and contamination of the resulting compost.

Compaction Prevention

The drum composting machine operates continuously, with 24-hour tumbling to ensure all material is adequately processed. This prevents compaction, unlike vertical fermenters.

Crop Safety

There is no risk of burning crops with the compost produced by the reactor. The compost reaches about 80% decomposition upon exiting the reactor. After a 30-day aging period, the temperature will not rise again, ensuring crop safety.

Wet Compost Handling

Excess water in the compost is removed during the stabilization and cooling (aging) process.

Gas Management

Gases produced during composting are primarily water vapors, which are released into the atmosphere through a deodorizing exhaust unit.

Bioreactor Composting

Bioreactor composting is a closed system for converting organic waste with zero emissions. It accelerates the physical, chemical, and biological processes of conventional composting, producing high-quality compost ready for crops.

1. Easy and Quick Installation: Simple setup with minimal space requirements.

2. Efficient Operation: Reduces waste management time by up to 95%.

3. Space-saving: Requires up to 90% less space than traditional systems.

4. Environmental Benefits: No unpleasant odors, leachate, pests, or greenhouse gases.

5. Cost-effective: Economical in the medium to long term.

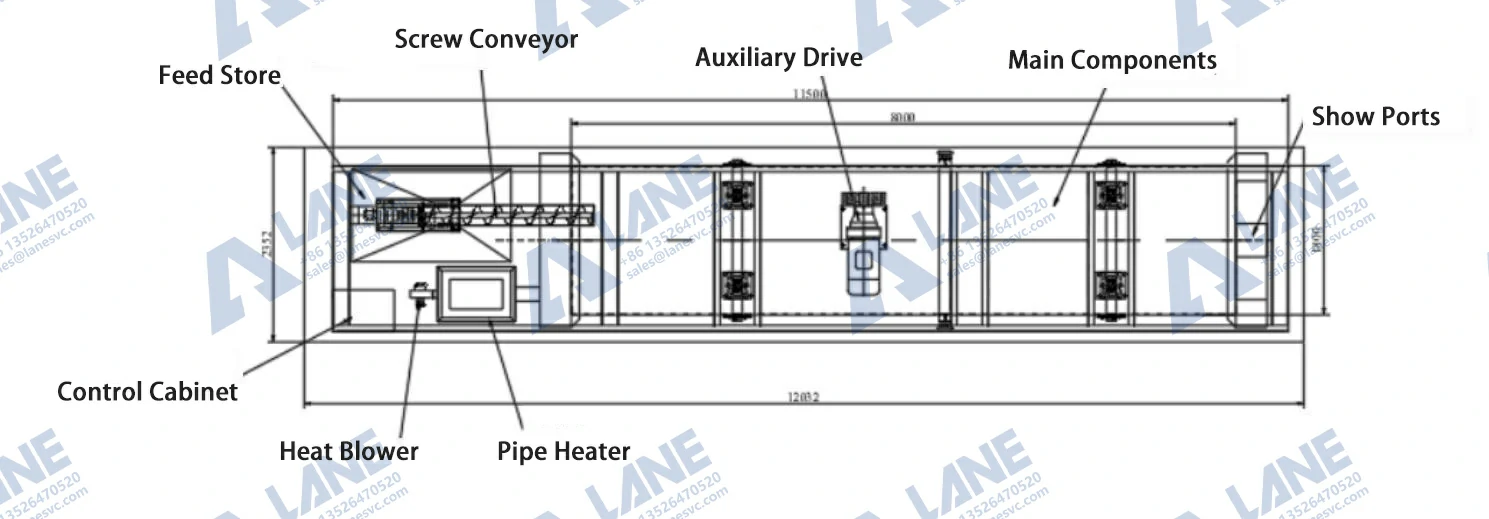

System Components

1. Mixer: Homogenizes waste before it enters the bioreactor.

2. Conveyor Belt: Feeds the mixed waste into the bioreactor.

3. Bioreactor: The main processing unit.

4. Deodorization System: Treats gases produced during composting.

Technical Specifications

1. Maximum Temperature: 65°C inside the bioreactor.

2. Service Life: Up to 20 years.

3. Power Consumption: Depends on the bioreactor size, ranging from 0 to 6.0 KWH.

The drum composting machine offers a highly efficient, automated solution for organic fertilizer production, transforming various organic wastes into valuable compost with minimal environmental impact.