1) Belt conveyor is a kind of friction-driven machinery to transport materials in a continuous way.

2) It is mainly composed of frame, conveyor belt, rollers, drum, tensioning device, transmission device and so on.

3) Belt conveyor can form a kind of material conveying process from the initial feeding point to the final unloading point on a certain conveying line.

4) It can not only carry out the transportation of broken materials, but also can carry out the transportation of pieces of goods.

5) In addition to pure material transportation, but also with the requirements of the production process in the production process of various industrial enterprises to form a rhythmic flow of transportation line.

It is an important transportation tool indispensable for realizing the automated mass production of fertilizer production line.

| Model | Capacity(tph) | Width(mm) | Speed(m/s) |

| B500 | 30-60 | 680 | 1.25-2.0 |

| B600 | 50-80 | 780 | 1.25-2.0 |

| B650 | 70-100 | 830 | 1.25-2.0 |

| B800 | 90-120 | 980 | 1.25-2.0 |

| B1000 | 110-140 | 1180 | 1.25-2.0 |

1) Conveying part: Considering the large friction with materials, we specially choose high quality anticorrosive and wear-resistant materials, which greatly improves the service life of the machine.

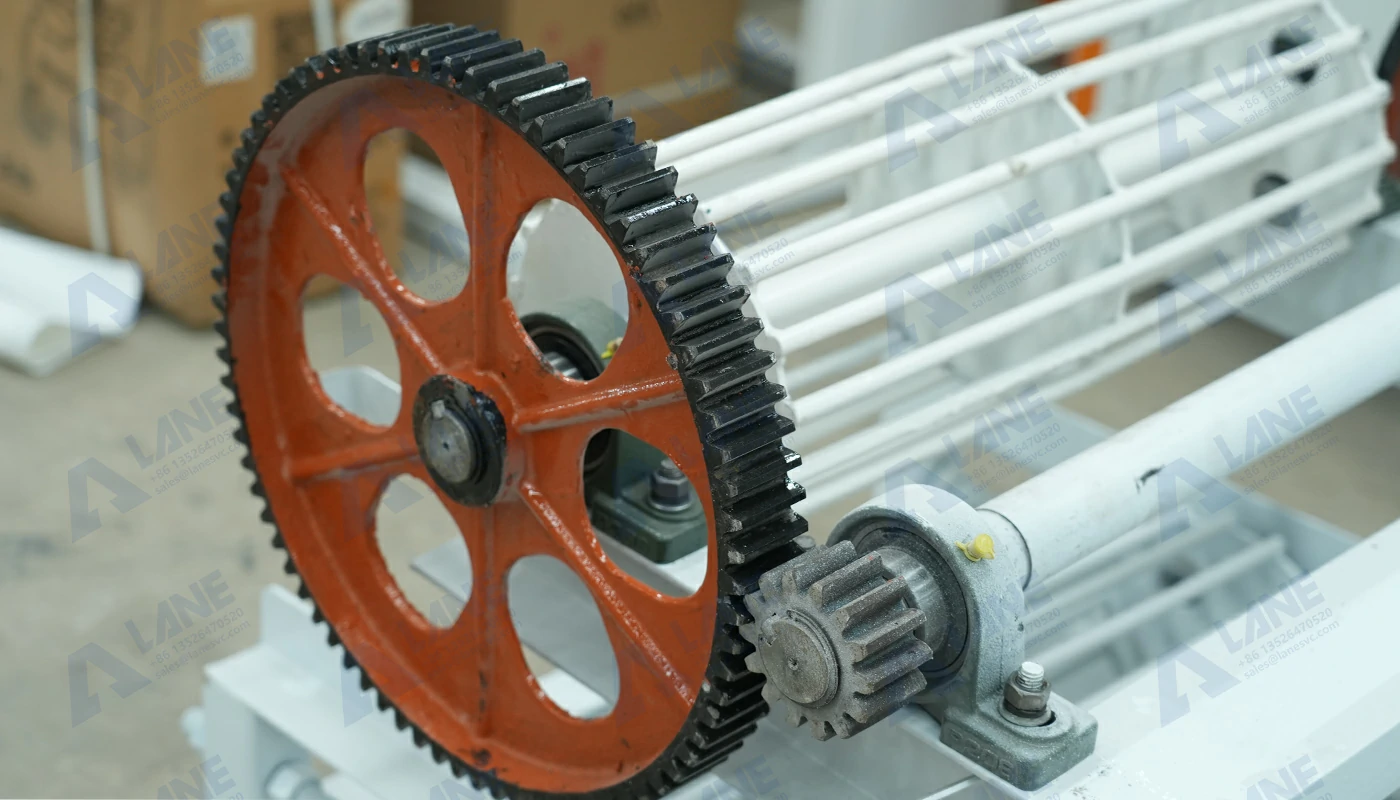

2) Transmission part: the whole belt conveyor transmission part is particularly important, the work of the entire body are thus. The motor drives the pulley to drive the gear and finally drive to the roller, drive the herringbone belt rotation, so that the body work.

3) Body part: the most important part of the whole belt conveyor is the body part, which is made of high-quality medium-carbon channel steel welding, high quality, good stability.

Belt conveyor mainly consists of two end-point rollers and the closed conveyor belt on the tight set.

1) The roller that drives the conveyor belt to rotate is called the driving roller; the other roller that is located in the direction of changing the movement of the conveyor belt is called the redirecting roller.

2) The drive roller is driven by the motor through the pulley, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt.

3) The driving roller is generally installed at the discharge end to increase the traction force, which is favorable for dragging.

4) The material is fed from the feeding end, falls on the rotating conveyor belt, and is transported to the discharging end by the friction of the conveyor belt.

1) High transportation efficiency: the belt machine can continuously and stably transport materials without stopping or transferring, which greatly improves the production efficiency and work efficiency.

2) Strong adaptability: the belt machine can be adjusted and modified according to different working environment and material characteristics, applicable to a variety of different production lines and process requirements.

3) Long transmission distance: the belt conveyor can convey materials from the starting point to the end point, and the transmission distance can be very long, which can meet the demand of long-distance conveying.

4) Large loading capacity: the belt conveyor can carry a large amount of materials and has a large loading capacity, which can meet the demand for large-volume material conveying in the production line.

5) Low maintenance cost: the belt conveyor has simple structure, relatively low maintenance cost, and it is convenient to repair and replace the parts.

6) High degree of automation: the belt conveyor can be linked with other equipment to realize automated production, reduce manual operation and improve production efficiency and safety.

In summary, the belt machine in the fertilizer production line has the advantages of high efficiency, stability, adaptability and so on, and can meet the needs of large quantities and long distances of material conveying.

However, due to the limitation of friction, the transportation effect of belt conveyor will not be ideal after the inclination angle is more than twenty, if you need to transport at a large angle due to the limitation of the site, the large inclination angle belt conveyor or bucket elevator will give you a better use of the effect.

We not only provide high quality products, but also offer a full range of customer service, always upholding the service concept of “the most suitable is the best“.

Whether it’s pre-sales consultation, technical support or after-sales service, our professional team will do their best to make sure you get the best experience and satisfaction when using our belt conveyors.