author: Zero Shen

from: LANE Machinery Groups

The seafood industry generates millions of tons of shellfish waste annually—discarded crab, shrimp, lobster, and oyster shells that often end up in landfills. This isn’t just waste; it’s a missed opportunity. Shellfish shells are a rich source of calcium carbonate, chitin, and micronutrients, making them a fantastic raw material for high-value organic fertilizer.

As a leading manufacturer of fertilizer production equipment and solutions, LANE provides the complete machinery line to transform this challenging waste stream into a profitable, eco-friendly product. This guide details the entire process and the essential shell fertilizer making machines you’ll need.

Before diving into the process, let’s understand the benefits. Shell-based organic fertilizer:

Improves Soil Health: Neutralizes soil acidity and enhances microbial activity.

Provides Slow-Release Calcium: Essential for strong cell walls in plants and preventing disorders like blossom-end rot.

Contains Chitin: This natural compound helps suppress soil-borne nematodes and fungi.

Promotes Sustainability: Diverts waste from landfills and creates a circular economy.

Setting up a successful shell fertilizer production line requires a systematic approach and robust machinery. Here is a step-by-step breakdown.

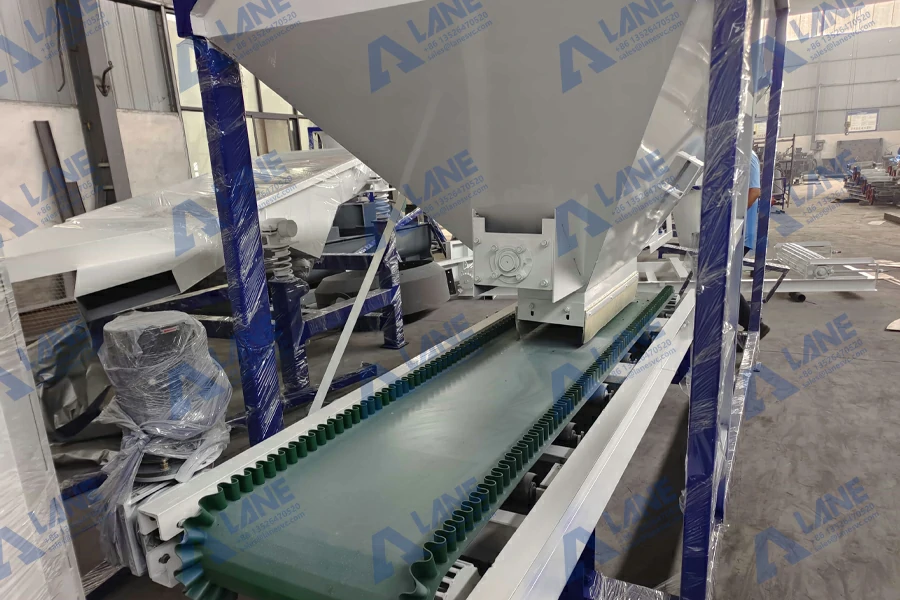

First, shells must be collected and separated from organic residue (meat, tissue). A thorough washing is crucial to remove salt and remaining organic matter, preventing odor and contamination in the final product. While this step is often manual, we can integrate fertilizer equipment like conveyor belts and washing systems for large-scale operations.

This is a critical step. Whole shells are bulky and slow to decompose. A shell crusher or grinder is used to pulverize the shells into a fine powder.

Key Equipment: Hammer Mill or Crusher Machine for Shells.

Function: Reduces shell size to a uniform powder or small particles, increasing the surface area for faster decomposition and reaction in subsequent steps.

Our Solution: Our heavy-duty hammer mills are specifically designed to handle the hard, abrasive nature of shells, ensuring consistent particle size and high throughput.

The ground shell powder is now ready for composting. To create a balanced organic fertilizer, it’s often mixed with other nitrogen-rich organic materials like livestock manure, plant straw, or food waste.

Key Equipment: Compost Turner (Windrow Turner).

Function: The mixture is formed into long rows (windrows). The compost turner regularly mixes and aerates the piles, ensuring even fermentation, temperature control, and odor reduction. This process matures the fertilizer and eliminates harmful pathogens.

Our Solution: We offer a range of compost turning machines, from simple groove-type turners to advanced self-propelled models, suitable for any production scale.

While powdered fertilizer is effective, granulating it makes it easier to handle, store, transport, and apply. This step is essential for creating a market-ready, commercial product.

Key Equipment: Fertilizer Granulation Machine.

Function: This machine agglomerates the fine composted powder into uniform, dense pellets. A organic fertilizer granulator is commonly used for organic materials. A binder may be added to improve granule strength.

Our Solution: Our granulation systems are highly efficient and can be customized to produce the desired granule size (e.g., 2-4 mm or 4-6 mm pellets) for your target market.

The newly formed granules have high moisture content and need to be dried to ensure storage stability.

Key Equipment: Fertilizer Dryer and Fertilizer Cooler.

Function: A rotary dryer uses hot air to reduce the moisture content of the granules. Subsequently, a rotary cooler brings the temperature down gently, preventing caking and preparing the granules for packaging.

Our Solution: Our drying and cooling systems are designed for energy efficiency and gentle product handling, preserving the quality of your organic fertilizer.

The final step involves screening out off-size granules and packaging the final product.

Key Equipment: Rotary Screening Machine and Automatic Packaging Scale.

Function: The screening machine separates the on-size granules from dust and oversized pellets, which are crushed and recycled back to the granulator. The final product is then weighed and bagged automatically.

Our Solution: We provide complete powder and granule packing machines to ensure a professional and efficient finish to your shell fertilizer production line.

Investing in a shell fertilizer plant is not just about buying individual machines; it’s about integrating a seamless system. As a professional fertilizer equipment manufacturer, we offer more than just hardware.

We provide:

Customized Fertilizer Production Lines: We design the layout and select the right combination of machines based on your raw material and output goals.

Turnkey Projects: From plant design and equipment installation to worker training and after-sales support.

Expert Technical Consultation: Our engineers help you optimize every step of the process for maximum efficiency and profitability.

Ready to turn shellfish shells into premium organic fertilizer?

Contact us today to discuss your project. Let our fertilizer production solutions and high-quality shell fertilizer making machines help you build a successful and environmentally responsible business.