1) Vertical crusher is widely used in the organic fertilizer production line and the compound fertilizer production line.

2) It has simple and reasonable structure, cost-effectiveness, high broken rate, energy saving, and less effected by the material with high moisture.

3) Vertical crusher is suitable for the crushing of raw materials and returns, especially adaptable for materials with high moisture rate.

4) It is not blocked easily and discharges material smoothly.

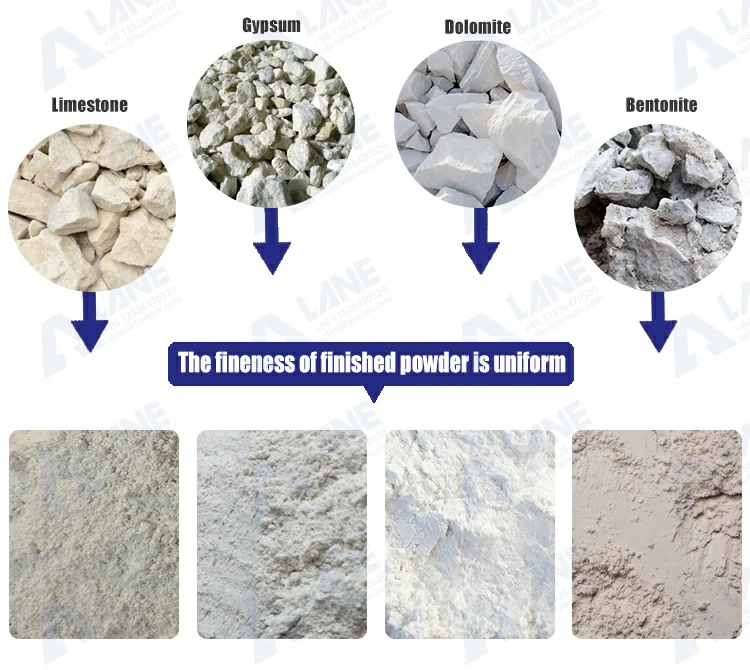

5) It can be used for the final crushing of limestone, cement clinker, mixed materials, gypsum, gangue, slag, copper ore, iron ore and other materials.

Vertical crusher is one of the most common crushing equipment used in compound fertilizer production line, suitable for raw materials and return material crushing, especially for the high water content of the material adaptability.

| Model | Capacity(tph) | Power(kw) | Overall Size(mm) | Input Size(mm) | Output Size(mm) | Main Shaft Diameter(mm) | Grinding Bin Diameter(mm) | Grinding Bin Height(mm) |

| LAC-60V | 4-6 | 18.5/4 | 1650*700*950 | 400*500 | 350*350 | φ65 | 600 | 650 |

| LAC-80V | 7-10 | 30/4 | 2100*1200*1100 | 400*500 | 350*350 | φ80 | 800 | 750 |

| LAC-100V | 9-12 | 37/4 | 2500*1300*1100 | 400*500 | 450*450 | φ100 | 1000 | 900 |

| LAC-120V | 12-15 | 55/4 | 1960*1316*2623 | 1000*1200 | φ500 | φ120 | 1200 | 753 |

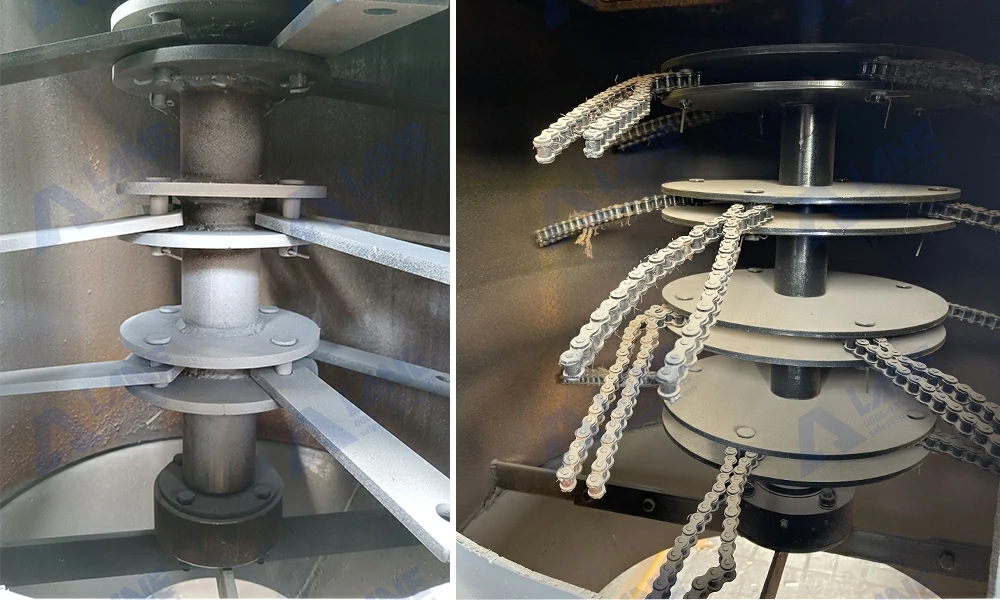

1) Vertical crusher consists of lower frame, shell, upper and lower shaft holders, main shaft, hammer head, hammer holder, pulley, motor frame and other parts.

2) The belt drives the main shaft to rotate, and there are two bearing seats on the main shaft, which are mounted on the upper and lower ends of the shell the casing is mounted on the lower frame, and the spindle is equipped with hammer head and hammer head holder.

3) The feed hopper is mounted on the upper part of the casing.

4) In order to facilitate the loading and unloading of the hammer head, the casing is equipped with a flap door, which is convenient for dismantling and maintenance.

1) The material enters from the inlet, and collides with the high-speed rotating blade in the machine shell.

2) The material is crushed and broken by the impact, and then impacted to the inner wall of the shell and then collided with the hammer head after counterattack.

3) After several impacts with different blades, the materials become powder or particles below 3mm in the process of falling and discharged from the lower part.

1) Simple and reasonable structure, cost-effectiveness. Using the principle of “stone hitting stone”, which has low abrasion.

2) High grinding rate and energy saving.

3) With fine crushing and coarse grinding function.

4) Small influenced by the water content of raw materials, the water content can be about 8%.

5) Working noise is less than 75 decibels (db level), and less dust pollution.

6) Suitable for crushing medium-hard and super-hard raw materials.

7) The product forms into cubic shape, with high packing density and low iron pollution.

8) Impeller has less abrasion, and easy to maintain.

1) Before turning on the machine, please make sure that there are no iron objects in the machine cabinet.

2) Do not randomly replace the belt pulley, in case the speed is too high to make the crushing chamber explode, or the speed is too low to affect the efficiency of the coal rock

3) The vertical crusher should be empty for 2-3minutes after starting, to confirm that there is no abnormal phenomenon before feeding work.

4) Pay attention to the operation of the vertical crusher in a timely manner, feed the material uniformly, to prevent blockage of bogging, do not work for a long time to overload.

5) Regular inspection of the machine parts monthly, check the worm wheel, worm gear, lubricating block on the bolt, bearing and other moving parts are flexible rotation and wear.

6) If the machine is not used for a long time, the machine must be wiped clean all over, and the surface of the machine should be coated with anti-rust oil.