Turn organic waste into valuable compost in 7–20 days with our advanced in-vessel composting systems. Whether you are processing food waste, livestock manure, sludge, straw, or municipal waste, our enclosed, automatic and odor-controlled composters deliver reliable and continuous performance.

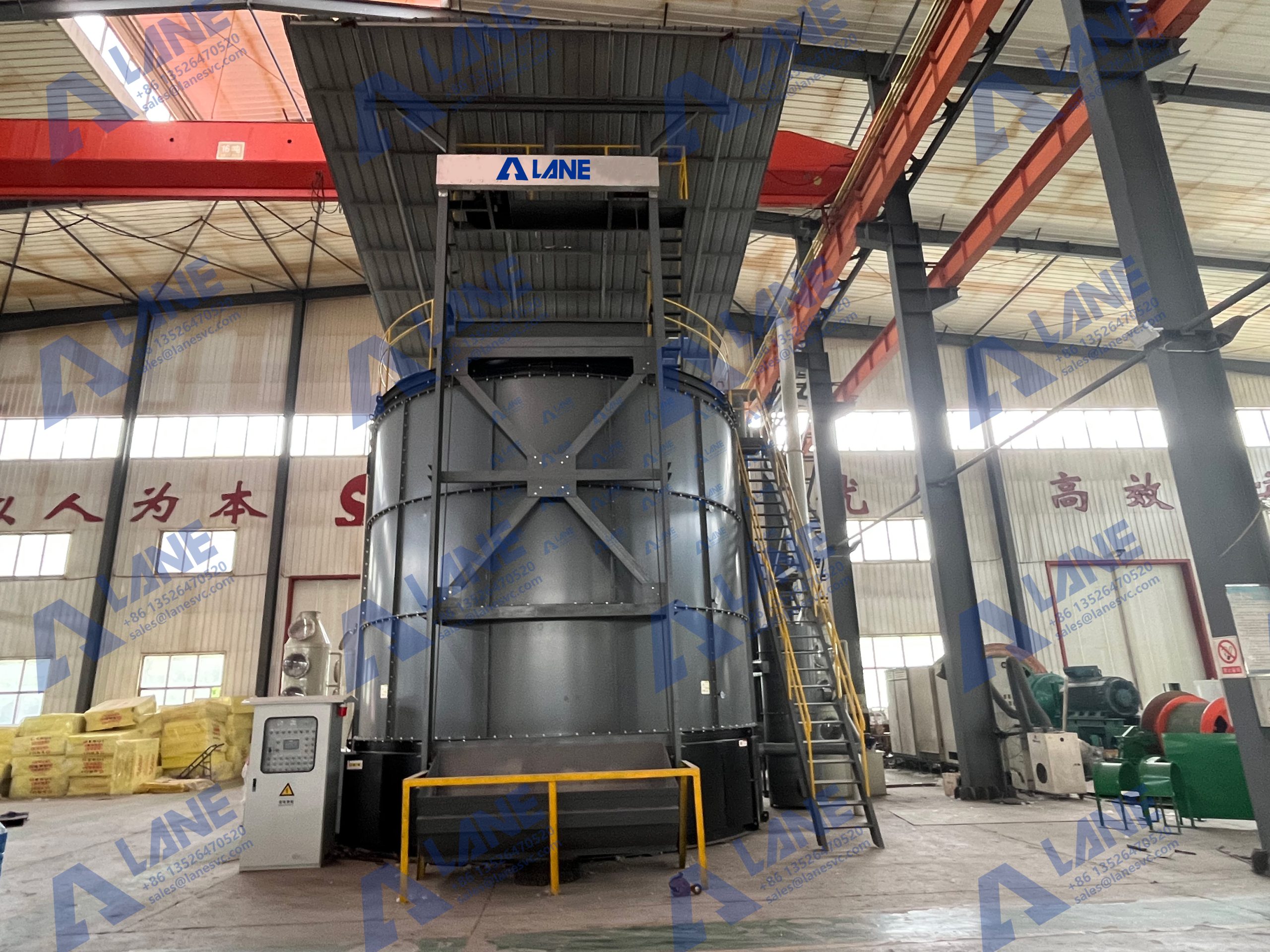

We provide three models: Vertical Fermentation Tank, Horizontal Fermentation Tank, and Rotary Drum Composter. All are fully enclosed in-vessel composting systems designed for rapid, clean and stable waste treatment.

Contact us today to receive a quotation and technical proposal.

Fully Enclosed Design

Prevents odor leakage and avoids secondary pollution. Suitable for farms, factories and urban waste management.

Rapid Fermentation (7–20 Days)

High-temperature aerobic fermentation ensures fast, safe, and complete composting.

Automatic Control System

Temperature, oxygen, moisture, turning and deodorization are controlled by the integrated PLC system.

Suitable for All Types of Organic Waste

Food waste, manure, sludge, straw, kitchen waste, biowaste and more.

Energy Saving and Durable

Made with stainless steel or customized materials according to project needs.

Compact, Space-Saving and Highly Efficient

Ideal for limited land areas such as restaurants, farms, food factories and community composting centers.

Working Principle:

Organic waste is fed into an insulated, vertical sealed tank where the agitator continuously stirs the materials. Through forced aeration and controlled temperature, aerobic microorganisms rapidly degrade the waste into stable compost.

Main Benefits:

Small footprint, high capacity

Automatic mixing and aeration

Intelligent temperature and oxygen control

Optional biofilter deodorization

24/7 operation with minimal maintenance

Capacity: 1–200 m³ (custom available)

Large Capacity and Industrial-Scale Processing

Designed for manure treatment plants, fertilizer factories and municipal waste centers.

Working Principle:

Waste materials enter a long horizontal insulated reactor where a screw-type mixing shaft slowly pushes and turns the materials. Oxygen is evenly distributed, ensuring uniform aerobic fermentation throughout the entire tank.

Main Benefits:

Excellent adaptability to different moisture contents

Screw mixing ensures uniform fermentation

Supports continuous or batch processing

Fully sealed and odor-free

Easy integration with conveyors, shredders and separators

Capacity: 1–100 m³ (custom available)

Continuous Operation and High Automation

Best suited for industrial-scale operations requiring fast and uniform composting.

Working Principle:

The reactor rotates at a constant speed, lifting and dropping the waste repeatedly. This ensures continuous aeration and heat distribution inside the drum, enabling fast high-temperature aerobic fermentation.

Main Benefits:

24-hour continuous composting

Uniform mixing and stable aeration

Short fermentation cycle (3–10 days)

Low operating cost

Suitable for large-volume waste treatment

Capacity: 1–300 tons per day(custom available)

Organic fertilizer production plants

Livestock and poultry manure treatment

Cattle farms, pig farms and poultry farms

Sludge composting

Food waste recycling

Government and municipal waste projects

University and community composting centers

Agricultural plantations and eco-farms

We provide complete technical solutions, including waste analysis, capacity design, layout planning, installation guidance and after-sales support.

Projects delivered to more than 60 countries.

Whether you need a vertical, horizontal or rotary drum composter, we design the exact system that matches your waste type and daily capacity.

Tell us your waste type and daily volume to receive specifications, pricing and engineering drawings.

Submit your contact information and our engineer will reply within 24 hours.