author: Zero Shen

from: LANE Machinery Groups

Abstract: As a new type of bio-fertilizer, algal-based fertilizer has the advantages of high fertilizer efficiency and environmental friendliness, which has received wide attention in recent years. This paper describes in detail a kind of algae-based fertilizer production line production technology with microalgae as raw material, including process flow, key equipment, technical parameters and quality control, etc., to provide reference for the industrial production of alga-based fertilizer.

Keywords: algae-based fertilizer; production process; microalgae; fermentation; granulation

Algae-based fertilizer refers to the fertilizer processed by fermentation, extraction, concentration, granulation and other processes using algae as raw materials. Algae is rich in protein, amino acids, vitamins, minerals and plant growth regulating substances, etc., which can promote the growth of crops, improve the yield and quality of crops, and at the same time, improve the soil structure and enhance soil fertility.

Algae-based fertilizer production line mainly includes the following processes:

Algae cultivation: Select microalgae species suitable for large-scale cultivation, such as Chlorella, Spirulina, etc., and carry out high-density cultivation in the photobioreactor.

Algae liquid harvesting: centrifugation, filtration and other methods are used to separate the algal cells from the culture liquid to obtain algal sludge.

Algae cell wall-breaking: Use high pressure homogenization, ultrasonic wave and other methods to destroy the wall of algae cells and release the cell contents.

Fermentation: The wall-broken algal liquid is connected with probiotics for fermentation to decompose algal macromolecules and generate small molecule active substances.

Concentration: Concentrate the fermentation solution to a certain concentration by vacuum concentration, membrane concentration and other methods.

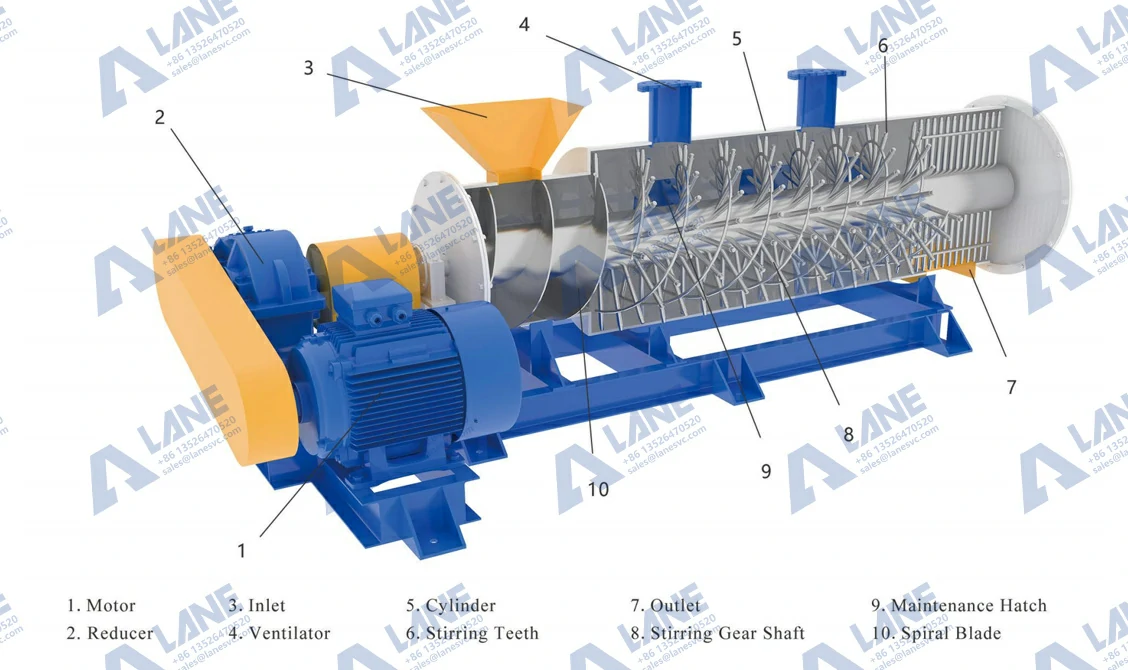

Pelleting: Mix the concentrated liquid with auxiliary materials, and make granular fertilizer by disc pelletizing, extruding pelletizing and other methods.

Drying: Use fluidized bed drying, drum drying and other methods to dry the granular fertilizer until the moisture content reaches the standard.

Cooling, sieving and packing: cool the dried fertilizer to room temperature, sieve out qualified products and pack them.

Photobiological reactor: adopt closed photobiological reactor, with light intensity of 1000-1500 μmol/(m²-s), temperature of 25-30℃, pH value of 7.0-8.0, and aeration volume of 0.5-1.0 vvm.

Centrifuge: adopts disc centrifuge, rotating speed 8000-10000 rpm, processing capacity 1-2 m³/h.

High pressure homogenizer: working pressure 50-80 MPa, processing capacity 0.5-1.0 m³/h.

Fermenter: stainless steel fermenter, volume 10-50 m³, temperature 30-35℃, pH value 6.5-7.5, aeration 1.0-1.5 vvm.

Vacuum concentrator: vacuum degree -0.08 ~ -0.09 MPa, evaporation temperature 50-60℃.

Pelletizer: adopts disc pelletizer, speed 20-30 rpm, inclination angle 45-60°.

Fluidized bed dryer: inlet temperature 80-100℃, outlet temperature 50-60℃, drying time 20-30 min.

Raw material control: select high quality algae and auxiliary materials, strictly control the quality of raw materials.

Process control: Strictly monitor each production link to ensure the stability of process parameters.

Product testing: Test the finished products for nutrients, microbial indicators, heavy metal content and so on, to ensure that the product quality meets the standards.

This paper introduces the algae-based fertilizer production line production process technology is mature and reliable, and can realize the large-scale production of algae-based fertilizer. The algae-based fertilizer produced by this technology has the advantages of high fertilizer efficiency, environmental friendliness, etc., and has a good market prospect.