author: Zero Shen

from: LANE Machinery Groups

As a naturally occurring mineral rich in calcium and magnesium, dolomite plays a pivotal role in fertilizer production. Compound fertilizers incorporating dolomite powder offer higher economic returns than nitrogen-phosphorus-potassium fertilizers, optimize soil structure, and enhance fertilizer efficiency, establishing them as a highly competitive presence in the fertilizer market.

The global dolomite market was valued at approximately USD 1.92 billion in 2023 and is forecast to reach USD 3.42 billion by 2032, growing at a CAGR of nearly 7.6% driven by construction, agriculture, and steel sectors.

In this growth trend, dolomite’s agricultural uses (such as soil conditioners, fertilizers, additives, etc.) are steadily rising. Growing focus on comprehensive nutrition drives efforts to incorporate more trace elements, enhancing product competitiveness.

At the same time, South American fertilizer markets have seen policy-driven shifts. For example, Brazilian state-run Petrobras is targeted to supply roughly 20% of national nitrogen fertilizer demand by 2026 through restarting idle plants — a move aligned with federal goals to lessen import dependence and improve domestic production capability.

Despite this, challenges in fertilizer production persist: Due to market volatility and operational pressures, some leading fertilizer producers have initiated strategic adjustments in Latin America, gradually scaling back their production efforts in the region.

Dolomite (chemical formula CaMg(CO₃)₂) supplies both calcium (Ca) and magnesium (Mg) — two secondary nutrients often deficient in tropical and subtropical soils. It also plays multiple roles in fertilizer systems:

Adjusts soil pH and improves acidic soil conditions

Supplies magnesium necessary for chlorophyll synthesis

Acts as a mineral carrier in NPK and blended fertilizers

Improves granule strength and flowability in compound fertilizers

These functions are critical in soils where nutrient imbalance and acidity limit crop yields.

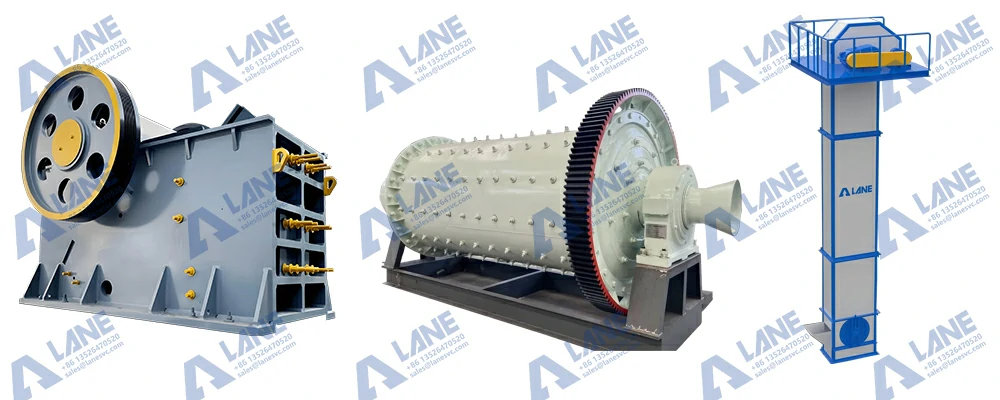

Designing a 100,000 tons/year dolomite npk fertilizer line goes beyond simple crushing. A modern industrial plant integrates mineral processing with fertilizer manufacturing systems. Typical configuration includes:

Raw Material Handling & Crushing

Ore size reduced by jaw crusher or hammer crusher

Uniform feed size for downstream grinding

Grinding & Powder Production

Processing with mills (e.g., raymond or vertical mills)

Final powder particle size range: 500–800 mesh, suitable for fertilizer and granulation systems

Moisture & Product Conditioning

Controlled final moisture ≤ 1%–1.5% to ensure storage stability and prevent caking

Precise blending systems prepare raw mix for granulation

Granulation

LARD drum granulator series produces stable mineral granules

Granule size controlled to meet customer application requirements

Drying & Cooling

Rotary dryers with staged airflow

Cooling section ensures product stability before packing

In large-scale fertilizer production, performance metrics matter:

Energy Consumption

Typical energy usage ranges between 23–30 kWh per ton of finished mineral product

Includes grinding, mixing, and granulation stages

Dust & Emissions

Equipped with advanced dust collection systems

Post-treatment emissions controlled to < 25 mg/m³, meeting strict environmental standards

Automation & Control

Integrates Siemens / ABB / Schneider electric drives and control systems

PLC automation for consistent operation and quality tracking

These parameters ensure consistent product quality while optimizing power usage and environmental compliance.

Processed dolomite serves multiple fertilizer roles:

1. Magnesium-Calcium Fertilizer

Dolomite is used directly as magnesium-calcium fertilizer in regions with Mg-deficient soils. Its slower-release profile makes it suitable for long-term soil conditioning.

2. Addition in NPK Blends

As a filler and pH modifier, dolomite enhances properties of NPK blends — especially in granule shape, density, and nutrient balance.

3. Organic & Mineral Mixes

Integrated in organic fertilizer blends, dolomite improves mineral nutrient content while supporting soil health over time.

For 100,000 t/a-class fertilizer plants in markets like Bolivia and broader South America, project success hinges on:

Turnkey EPC delivery capability, minimizing commissioning time

High-quality equipment design and European automation

After-sales services and remote technical support

Adaptation to local mineral characteristics and climate conditions

This ensures plants deliver market-ready products with minimal downtime and consistent performance.

Amid global fertilizer market shifts and agricultural productivity demands, dolomite for fertilizer production offers dual advantages of soil improvement and nutrient enrichment. Through LANE designed dolomite compound fertilizer production plant, natural dolomite is processed into calcium-magnesium compound fertilizer granules, meeting evolving market fertilizer requirements.

As a Chinese fertilizer equipment manufacturer with 20 years of experience, LANE has partnered with clients across multiple countries. Leveraging technical expertise and strategic project delivery capabilities, we have successfully constructed industrial-scale fertilizer plants that achieved smooth commissioning.

If you are interested in initiating a dolomite for fertilizer production project, feel free to contact us anytime to obtain your customized solution!