author: Zero Shen

from: LANE Machinery Groups

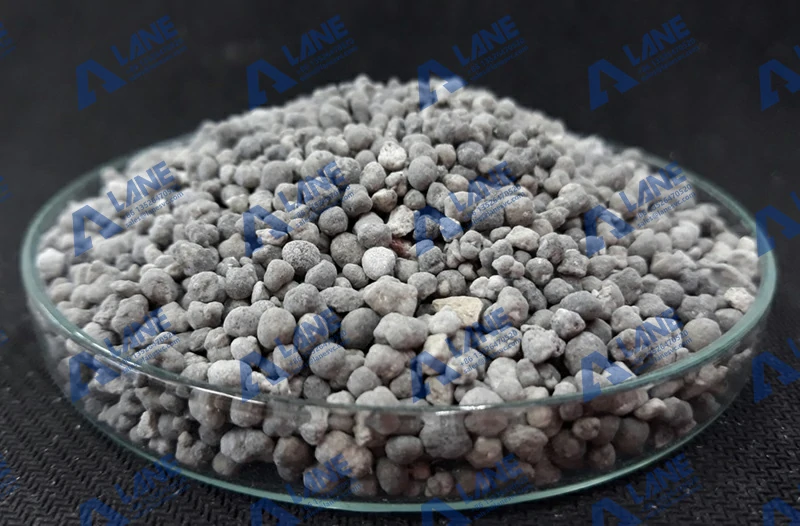

Calcium superphosphate fertilizer(SSP) production line is the equipment and process used to produce calcium superphosphate fertilizer. Calcium superphosphate is a kind of fertilizer containing many nutrients, mainly including phosphorus, calcium and sulfur, which can increase the fertility of soil and improve the yield and quality of crops.

Calcium superphosphate fertilizer (SSP) is a phosphorus containing fertilizer produced by the chemical reaction of phosphate ore and sulfuric acid. LANE Heavy Industry uses the dilute acid ore powder method to produce superphosphate. The phosphate ore powder and dilute sulfuric acid are mixed in a mixer, then solidified in a chemical chamber, dried and granulated to obtain the finished superphosphate product. Finally, through material accounting and heat accounting, a production line that meets national standards is designed, This ssp production line is suitable for most low-grade phosphorus ores, with low energy consumption, stable quality, low investment, and fast capital recovery.

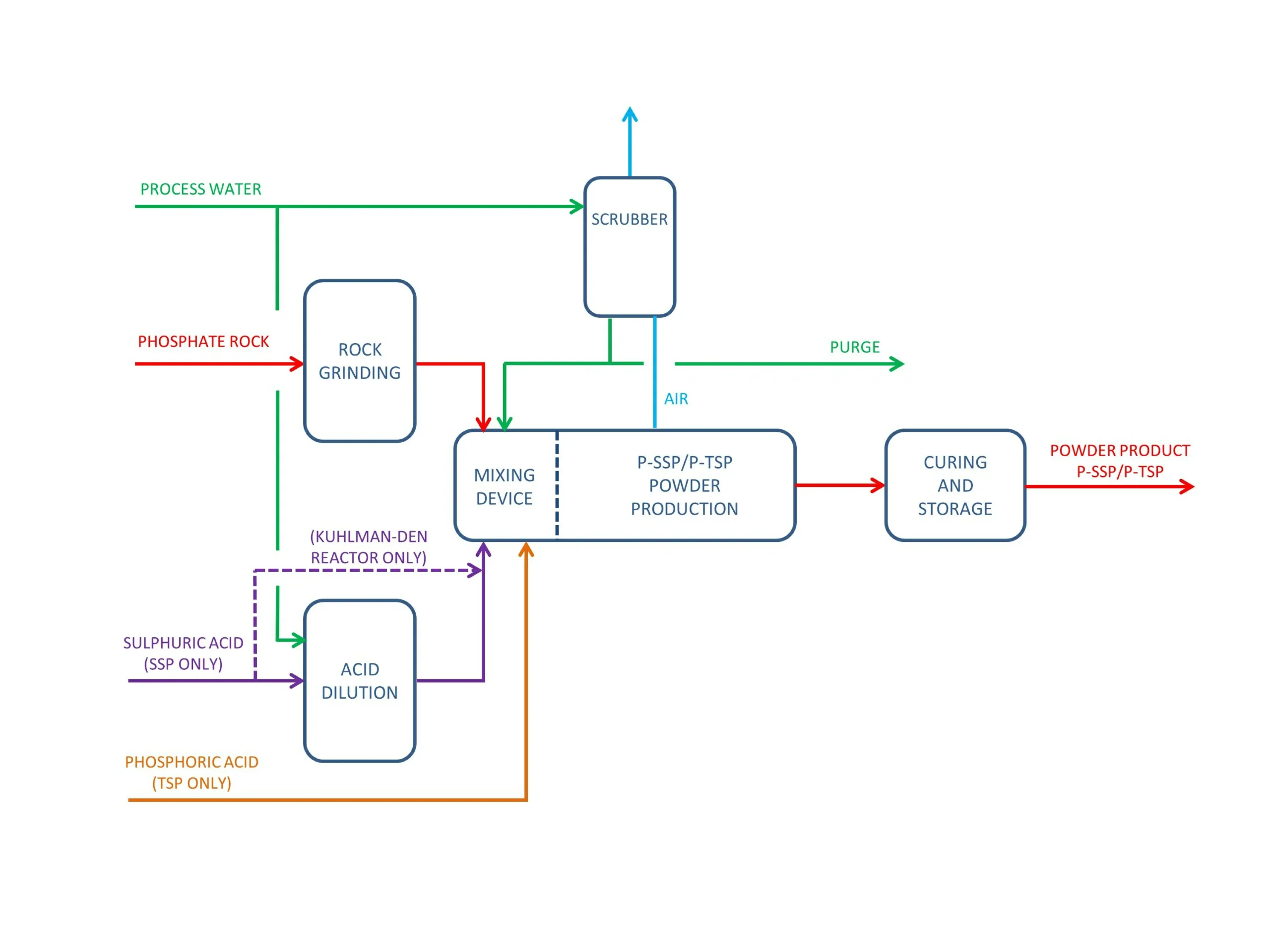

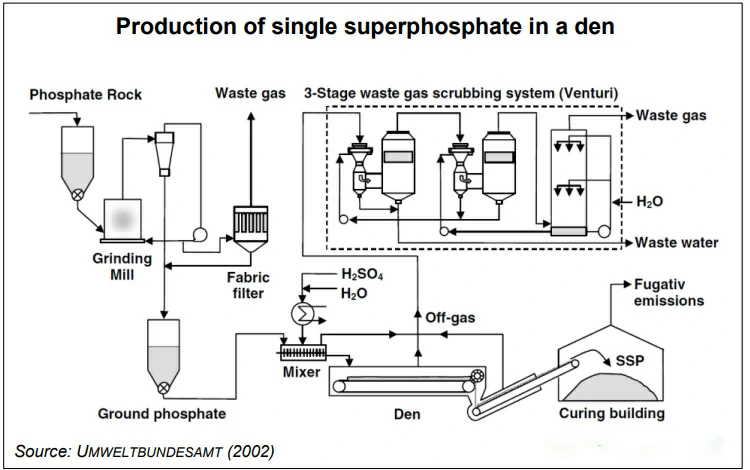

(1) Sulfuric acid is mixed with phosphate powder;

(2) Slurry is formed in the formation room;

(3) Calcium superphosphate is matured in the warehouse;

(4) Recovery of fluorine from fluorine-containing waste gas;

(5) Drying and granulation.

Production process method of calcium phosphate

1) Dilute acid mineral powder method

It is made by mixing dilute sulfuric acid with phosphate rock powder with a concentration of 68% to 72%, and then preparing powdered superphosphate through the process of formation and maturation.

2) Concentrated acid slurry method

The concentrated acid slurry method involves mixing concentrated sulfuric acid with phosphate slurry that has been wet ground with water, and then undergoing the same process of formation and maturation to produce powdered superphosphate.

Wet grinding of phosphate rock results in a steel ball consumption in the mill that is about 4-6 times higher than that of dry grinding. At the same time, in order to make the slurry flowable, the minimum moisture content of the slurry varies depending on the type of ore. The minimum moisture content of the slurry of hydrophilic phosphate rock is relatively high, causing the water content of the superphosphate product produced using it to exceed the quality standard requirements and hindering the physical properties of the product.

In this increasingly competitive market, we have been committed to providing our customers with high quality fertilizer machinery products and excellent service, so that they can buy the most satisfactory products at the most affordable prices.

After our research and development and continuous adjustment, the calcium superphosphate production line(ssp production line) equipment has begun to be manufactured, all of which adopt the most advanced technology and process, with high efficiency, stability, energy saving and other characteristics, which can bring your production line more benefits and profits.

We believe that choosing our products and services is an important guarantee for your success in the fertilizer industry. Let’s join hands to create a better future!