author: Zero Shen

from: LANE Machinery Groups

FMP Fertilizer Production Line: Transforming Low-Grade Phosphate Rock into Eco-Friendly Fertilizer

Fused Magnesium Phosphate (FMP) is a citrate-soluble, slow-release phosphate fertilizer produced through high-temperature fusion and rapid quenching. Its unique properties make it ideal for acidic soils:

| Property | Traditional P-Fertilizers | FMP Fertilizer |

|---|---|---|

| P Solubility | Water-soluble (prone to fixation) | Citrate-soluble (releases in weak acids) |

| Raw Material | Requires high-grade ore (P₂O₅≥28%) | Accepts low-grade ore (P₂O₅≥12%) |

| Soil Compatibility | Neutral/alkaline soils | Optimized for acidic soils (pH<6.5) |

| Added Nutrients | Phosphorus only | P + Mg + Ca + Si (soil conditioner) |

| Environmental Impact | Generates phosphogypsum waste | Zero solid waste (only HF gas treatment) |

FMP fertilizer production line can convert low-value phosphate rock into long-lasting P-fertilizer while improving acidic soil structure.

A complete FMP fertilizer production line comprises 4 critical sections:

Process: Crushing → Drying → Grinding → Blending

Key Equipment:

Jaw Crusher: Primary size reduction (300–500 mm → 50–80 mm).

Rotary Dryer: Reduces moisture to <5% (fuel: natural gas/biomass).

Ball Mill: Pulverizes ore to 80–100 mesh (0.15–0.18 mm).

Automatic Batching System: Precision blending of phosphate rock (e.g., fluorapatite) and magnesium sources (olivine/serpentine) at 3:1–4:1 ratio.

Process: Melting (1,350–1,500°C) → Chemical reaction → Molten material handling

Key Equipment:

Submerged Arc Furnace (or Rotary Kiln):

Power: 8–12 MW for 50K t/yr capacity

Lining: Magnesia-carbon refractory bricks

HF Exhaust System:

High-temperature ducting → Quench tower → Scrubber (converts HF to Na₂SiF₆ byproduct).

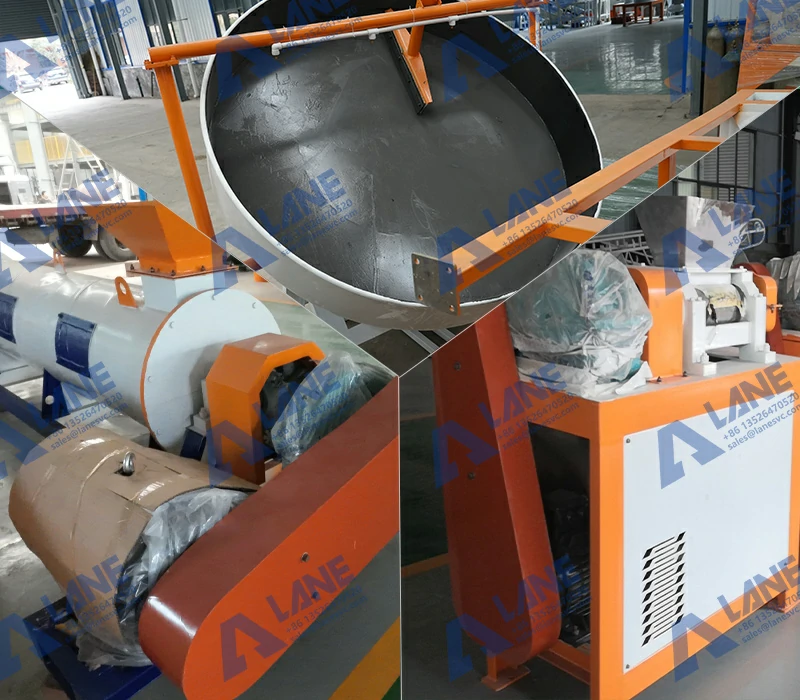

Process: Water quenching → Drying → Crushing → Screening

Key Equipment:

Granulator: Molten stream + high-pressure water → Porous glassy granules (1–5 mm).

Rotary Cooler: Cools granules to <80°C.

Chain Crusher: Reduces oversized particles to powder.

Vibrating Screen: Separates product into 2–4 mm granules (yield: 85–90%).

Process: Neutralization (optional) → Packaging → Storage

Key Equipment:

Ammoniation Drum: Sprays NH₃ gas to adjust pH (optional).

Automatic Bagging Scale: 25–50 kg PP/PE woven bags with moisture barrier.

| Aspect | Benefit |

|---|---|

| Flexibility | Processes low-grade ores rejected by SSP/TSP plants |

| Energy Recovery | Waste heat powers pre-drying (cuts fuel use 15–20%) |

| Eco-Design | Zero solid waste; HF converted to marketable Na₂SiF₆ |

| Automation | PLC-controlled batching/fusion (≤3 operators/shift) |

Target Markets: Acidic lateritic soils (Latin America, West Africa, Southeast Asia).

Innovation Frontiers:

Co-granulation: Blending FMP with biochar/K-humate for premium products.

Zero-Emission HF Capture: Electrostatic precipitation + Na₂CO3 absorption (99.5% efficiency).

AI Optimization: Machine learning for real-time furnace temperature/ratio control.

As a leading fertilizer equipment manufacturer, our FMP fertilizer production line integrates patented innovations that deliver unmatched operational efficiency and ROI. Key equipment strengths include:

Deep-Chamber Arc Design

15% wider molten pool vs conventional furnaces → ↑20% hourly throughput

Multi-layer refractory (MgO-C + Al₂O₃-ZrO₂ composite) → 36-month campaign life (industry avg: 24 mo)

Intelligent Electrode Control

Auto-adjustment via current/resistivity sensors → Stable melt temp (±5°C) | ↓15% electrode consumption

| Feature | Standard Equipment | Our Innovation | Benefit |

|---|---|---|---|

| Nozzle Design | Single-orifice | Spiral-Turbine Jet | Self-cleaning → Zero downtime for clogging |

| Material Contact | Carbon steel | Hastelloy C276 + WC Coating | Corrosion resistance → 10x lifespan |

| Water Efficiency | 12 m³/ton | 8.5 m³/ton | Saves 3,500 m³/month for 50kt/yr line |

Triple-Pass Rotary Dryer

Countercurrent airflow + internal lifters → 30% faster moisture removal

Waste heat recovery from fusion exhaust (450°C → 180°C) → ↓100% auxiliary fuel need

AI Moisture Control

NIR sensors + predictive algorithms → Product moisture stability: 5±0.3%

Equipment Health Monitoring

Vibration sensors on crushers/mills → Predict failures 72+ hrs in advance

Furnace thermal imaging → Detect refractory wear at Stage 1

Modular Component Design

Quick-release rollers, cartridge bearings → ↓40% repair time

FMP fertilizer production lines offer a sustainable pathway to valorize low-grade phosphate resources while addressing soil acidity – a growing concern in tropical agriculture. With modular designs and improving automation, CAPEX barriers continue to decrease, positioning FMP as a key player in the next generation of eco-smart fertilizers.

Why Partner With Us?

Our FMP fertilizer production lines aren’t just machinery – they’re turnkey profit generators. From ore to bagged fertilizer, we engineer every component to maximize availability, minimize costs, and future-proof your investment in the acidic soil revolution.