Fulvic acid, a substance derived from the essence of natural humus, has become an indispensable type of fertilizer for modern and efficient agriculture with its powerful soil improvement ability, promotion of plant nutrient uptake and enhancement of resistance.

With the increasing global attention to green agriculture and soil health, the market demand for fulvic acid fertilizer is surging, and investment in building a professional fulvic acid fertilizer manufacturing plant is ushering in a golden opportunity. The key to success lies in the precise control of core raw materials, scientific technology, and efficient and reliable production equipment.

I. Fulvic Acid Fertilizer Manufacturing Plant Core Raw Materials

The quality of fulvic acid comes from the selection of raw materials. We have developed fulvic acid fertilizer manufacturing plant solution after continuous experiments and improvements:

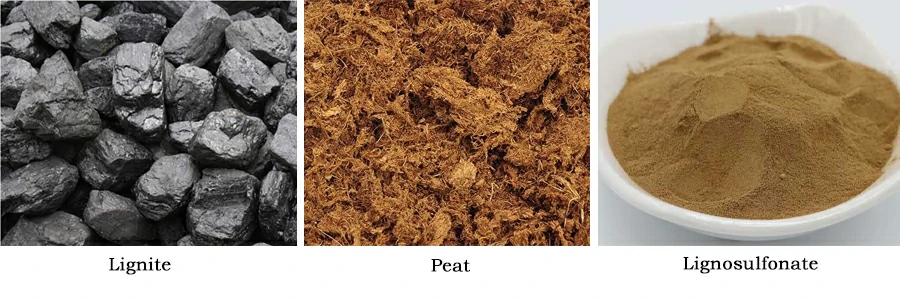

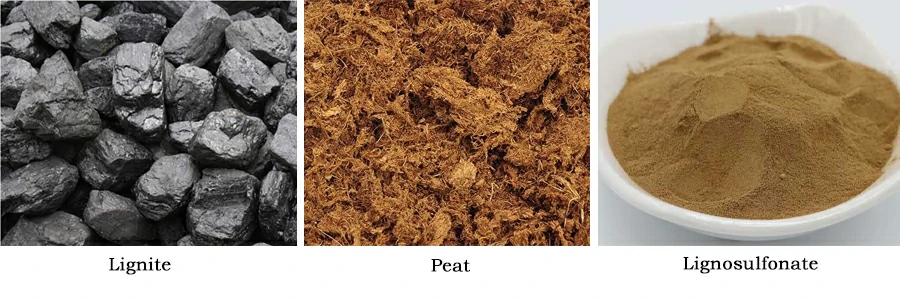

Carbon-rich organic matter:

- Lignite/weathered coal: the most common and cost-effective raw material. It contains humic acids (mainly brown and black humic acids) that need to be further activated and degraded. Our plants are optimized for their physical characteristics (e.g. high viscosity, potential impurities).

- Peat: Contains a high proportion of native humic acids (including xanthic acid) and is often of better quality, but is more costly and limited in availability. Equipment design takes into account its milder treatment needs.

- Lignin and its derivatives: By-products of the paper industry (e.g. lignosulfonates) are a renewable resource with great potential. Our process equipment effectively converts them into highly reactive, small molecule xanthic acid in a targeted manner.

- Agricultural waste: Straw, rice husk, etc. can also be used as a supplementary source of raw materials after appropriate pretreatment (e.g. fermentation, pyrolysis), reflecting the value of circular economy.

II. Fulvic Acid Fertilizer Manufacturing Plant: from waste to fulvic acid fertilizer

The fulvic acid fertilizer manufacturing plant we provide is a complete production system that can guarantee your project to be put into production quickly.

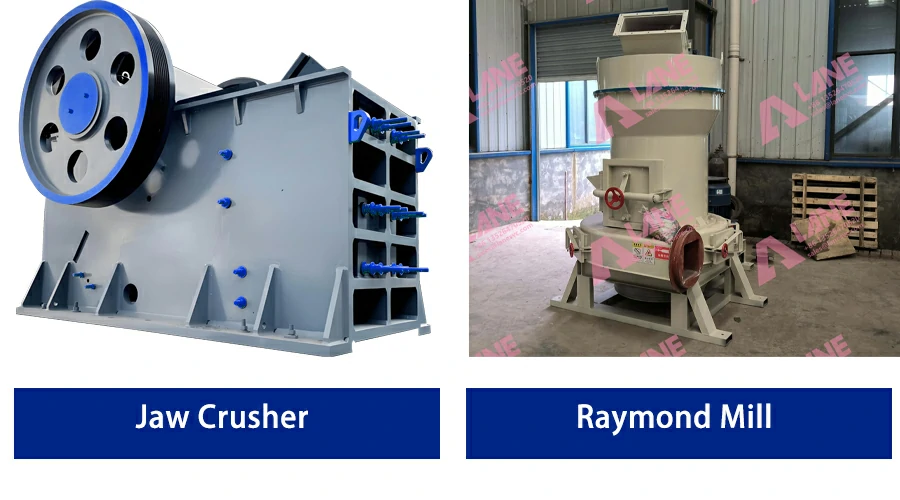

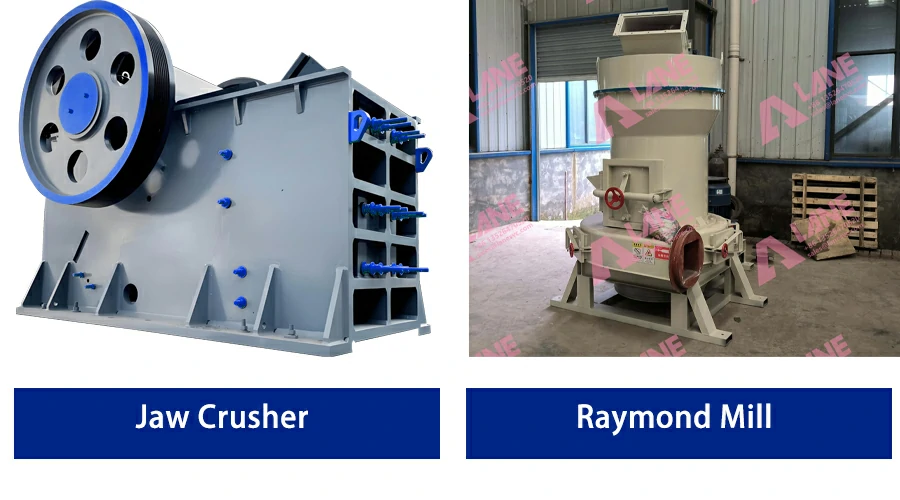

Pre-treatment of raw materials:

- Crushing & Grinding: Using a jaw crusher or Raymond mill, lumpy raw materials (e.g. lignite) are crushed to the target fineness (typically 80-200 mesh), which significantly increases the reaction contact area and improves subsequent extraction and oxidation efficiency.

- Screening: Vibrating screener removes impurities and large particles to ensure homogeneity of the feedstock.

Alkaline solubilization extraction:

- The crushed raw materials are mixed with a certain concentration of alkali solution (such as KOH solution) in a strong alkali corrosion-resistant reaction vessel.

- The vessel is equipped with a highly efficient variable frequency stirrer (anchor, paddle or turbine) to ensure adequate mixing of solids and liquids; the jacket or coil precisely controls the temperature (usually at 60-90°C) to optimize the extraction efficiency. The extraction time varies depending on the raw material and the efficiency of the equipment.

Solid-liquid separation (primary separation):

- The extracted mixture is separated through a filter.

- The filtrate (containing mainly humates) goes to the next process. The filtrate (containing mainly insoluble impurities and ash) can be considered for resource utilization or safe disposal. Our separation equipment is highly efficient, filtrate is clarified, filter cake is dry and loss of active ingredients is reduced.

Oxidation/degradation (fulvic acid fertilizer manufacturing plant core process):

- This step is the key to fulvic acid fertilizer manufacturing plant. Oxidizing agents (e.g. H₂O₂, K₂S₂O₈) are precisely and controllably added to the humate solution in a special pressure and corrosion resistant oxidation reactor.

The core advantages of the Fulvic Acid Fertilizer Manufacturing Plant:

- Precise Temperature Control System: Maintains optimal reaction temperature (often 60-80°C, higher for specific processes) to ensure stable and efficient reaction, avoiding over-oxidation or side reactions.

- Adjustable homogeneous mixing: Specially designed mixing systems (e.g. multi-layer turbine, high shear) combined with optional gas distributors (if O₃ or air is used) greatly enhance the gas-liquid/liquid-solid mass transfer rate, significantly reducing the reaction time and increasing the conversion rate of fulvic acid.

- Safety and reliability: Equipped with pressure/temperature sensors, safety valves, and an automatic release system to ensure absolute production safety under strong oxidizing environments.

- Precise metering and dosing: automated metering pumps precisely control the amount and speed of oxidizer and catalyst addition to ensure the consistency of product quality and process repeatability.

Acid precipitation purification and secondary separation:

- The oxidized solution is adjusted to acidic pH (usually pH 1-2) with acid (e.g. HCl) to precipitate fulvic acid.

- High purity wet fulvic acid filter cake is obtained again by high efficiency solid-liquid separation equipment (e.g., high-speed tube centrifuge or precision filter press). The separated acidic mother liquor can be partially reused or neutralized.

Drying and granulation (finished product sizing):

- Granulation: Using organic fertilizer granulator, the wet fulvic acid is granulated and shaped through the high-speed rotary shear of the pin.

- Belt drying/drum drying (granule/flake products): After the wet filter cake is shaped by granulator, it is dried by hot air penetration in multi-layer mesh belt dryer or rotary drum dryer to get granule products.

- Packing: The dried fulvic acid granules are packed by automatic quantitative packaging machine.

Investing in Fulvic acid fertilizer manufacturing plant is not only buying a machine, but also choosing the cornerstone of long-term stable profitability and market competitiveness. Our solutions are your bridge to new opportunities:

Strong technical support: As a leading enterprise of fertilizer equipment in China, we have been deeply cultivating fertilizer production equipment for more than 20 years, constantly improving and developing new equipment, gaining experience from practice, and now we have won a number of patented technologies.

Fulvic acid fertilizer manufacturing plant Core equipment, superior performance:

- Sturdy and durable, easy maintenance: the key equipments are made of top corrosion and abrasion resistant materials (such as reactor liner, valves, pump overflow parts), with scientific and reasonable structural design, which significantly reduces the failure rate, prolongs the service life, and minimizes the downtime and cost of maintenance. Optional Siemens/ABB and other motor brands, core components quality assurance.

- Modular design, flexible expansion: The equipment adopts modular design concept, which can be flexibly configured according to your initial investment budget and market demand (e.g. from thousands of tons to tens of thousands of tons per year), and reserve convenient upgrade and expansion interfaces to help you easily cope with future growth.

- Turnkey project, worry-free production: We provide a full range of “turnkey” services from process design, equipment manufacturing, installation and commissioning, personnel training to production guidance. Our experienced team of engineers ensures that your plant goes into operation smoothly and quickly reaches production standards.

Conclusion

In the booming wave of fulvic acid fertilizer market, mastering the core technology of advanced production process and equipment is your best chance to improve your competitiveness in the market.

We understand the essence of fulvic acid production and are committed to providing efficient, reliable, intelligent and durable complete equipment solutions. By choosing us, you not only get the top production tools, but also win a reliable partner for long-term cooperation.

Contact us now to get the exclusive fulvic acid fertilizer manufacturing plant plan and detailed quotation, and start your road to success!

More Video