As European agriculture increasingly prioritizes efficient nitrogen utilization, controlled-release fertilizers, and sulfur supplementation, sulfur-coated urea (SCU) has emerged as a strategic fertilizer product in the region, steadily gaining market competitiveness.

Recently, Lane sulfur-coated urea production line was successfully installed, commissioned, and is now operating stably in Europe. Prior to this, the client had no prior experience in fertilizer production. Leveraging its extensive expertise, LANE Machinery Groups successfully guided the client through the entire process, achieving a seamless transition from zero to full-scale production.

This European client, originally engaged in vineyard cultivation, has substantial and ongoing demand for fertilizers. To further reduce costs associated with imported fertilizers, they considered constructing a sulfur-coated urea plant.

Market analysis indicates:

– Sustained growth in demand for controlled-release nitrogen fertilizers

– Increasing concern over sulfur deficiency in European soils

– Premium pricing potential for sulfur-coated urea compared to bulk urea

However, the client faced critical technical barriers:

– Lack of process design experience for sulfur-coated urea plants

– Unfamiliarity with sulfur coating technology and quality control procedures

– Concerns regarding production stability, safety, and product consistency

The client searched online for sulfur-coated urea equipment suppliers, discovered LANE’s website, learned about our turnkey fertilizer production capabilities, and contacted us with their requirements.

After multiple discussions and meetings, LANE was ultimately selected as the project partner based on our comprehensive sulfur-coated urea production line solutions and international project experience.

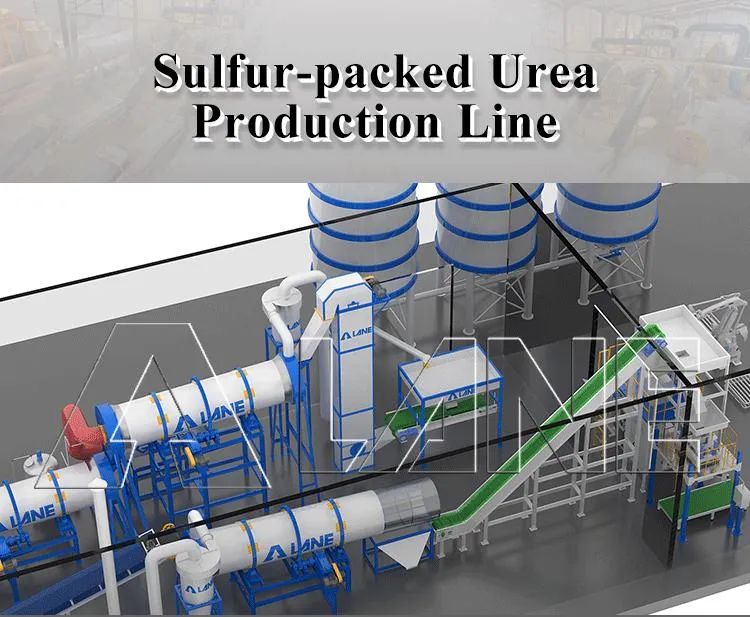

After the client outlined their ideas and requirements, Lane provided a solution for a medium-sized sulfur-coated urea plant with the following core parameters:

Designed capacity: 5–6 tons/hour

Annual output: approx. 30,000–40,000 tons (single shift operation)

Urea granule size: 2.5–4.0 mm

Sulfur coating ratio: 8%–15% (adjustable)

Nitrogen content (N): ≥ 36%

Sulfur content (S): 8%–12%

Key Equipment Included:

Urea melting and heating system (temperature control: 130–140°C)

Rotary sulfur coating drum with precision spraying system

Cooling and solidification unit

Screening system for uniform particle size

Automated control system with temperature and speed regulation

This Sulfur-Coated Urea Plant design prioritized operational simplicity, making it suitable for first-time operators and minimizing subsequent complications arising from complex processes.

Challenge 1: No Production Experience

The client’s technical team lacked hands-on fertilizer production knowledge.

LANE’s solution:

Step-by-step operation manuals

Remote commissioning guidance

Clear parameter presets for coating thickness, drum speed, and sulfur flow

Operators were able to master daily production within a short training period.

Challenge 2: Coating Uniformity at Initial Start-Up

During early trial runs, the client was concerned about coating consistency.

LANE’s solution:

Optimized coating drum rotation speed (typically 6–12 rpm)

Adjusted sulfur spray rate and urea feed ratio

Fine-tuned cooling air volume to ensure uniform sulfur solidification

As a result, coating uniformity exceeded 95%, meeting commercial quality standards.

Challenge 3: Product Stability and Storage Performance

The client required assurance that the product would perform well during storage and transportation.

LANE’s solution:

Controlled cooling to reduce sulfur cracking

Recommended anti-caking treatment

Verified crushing strength and abrasion resistance

Finished Sulfur-Coated Urea showed excellent storage stability and controlled-release performance.

After commissioning, the Sulfur-Coated Urea Plant achieved:

Continuous and stable operation for over 8 hours per shift

Product qualification rate above 98%

Smooth release behavior aligned with agronomic requirements

Positive feedback from downstream distributors

The client successfully transitioned from a fertilizer trader to a Sulfur-Coated Urea manufacturer.

This European project highlights LANE’s strengths:

Proven Sulfur-Coated Urea Plant technology

Engineering solutions tailored for new producers

Strong after-sales and technical support

Flexible capacity and coating ratio design

LANE focuses not only on equipment supply but on ensuring that each Sulfur-Coated Urea Plant operates reliably and profitably.

Building a Sulfur-Coated Urea Plant requires more than machinery—it requires process understanding, operational guidance, and engineering reliability.

LANE remains committed to supporting fertilizer producers worldwide with high-performance Sulfur-Coated Urea Plant solutions, from project planning to long-term operation.