Large inclination belt conveyor is a kind of continuous conveying equipment for conveying materials with large inclination angle or vertical direction. Besides being commonly used in fertilizer production line, it is also widely used in mining, electric power, metallurgy, chemical industry, etc. It is especially suitable for conveying bulk materials and lump materials.

It can effectively solve the problem that traditional conveying equipment can not convey materials with large inclination angle, and improve the conveying efficiency and conveying height of materials.

For conveying site has the limitation of assembly line production, large inclination belt conveyor is a good choice.

| Model | Capacity(m³/h) | Belt Conveyor Width(mm) | Overall Width(mm) |

| LAD-300 | Inclination angle 30° retaining edge 40/60: 14/15m³/h Inclination angle 45 ° retaining edge 40/60: 10/11m³/h Inclination angle 60 ° retaining edge 40/60: 7/8m³/h |

300 | 480 |

| LAD-400 | Inclination angle 30° retaining edge 60/80: 20/34m³/h Inclination angle 45 ° retaining edge 60/80: 14/26m³/h Inclination angle 60° retaining edge 60/80: 10/18m³/h |

400 | 580 |

| LAD-500 | Inclination angle 30° retaining edge 80/120: 46/71m³/h Inclination angle 45 ° retaining edge 80/120: 35/57m³/h Inclination angle 60° retaining edge 80/120: 25/40m³/h |

500 | 870 |

| LAD-650 | Inclination angle 30° retaining edge 120/160: 104/120m³/h Inclination angle 45 ° retaining edge 120/160: 83/97m³/h Inclination angle 60° retaining edge 120/160: 58/69m³/h |

650 | 1020 |

| LAD-800 | Inclination angle 30 ° retaining edge 120/160/200/240: 128/157195/235m³/h Inclination angle 45 ° retaining edge 120/160/200/240: 102/127/157/195m³/h Inclined angle 60 ° retaining edge 120/160/200/240: 72/90/112142m³/h |

800 | 1220 |

| LAD-1000 | Inclination angle 30 ° retaining edge 120/160/200/240: 172/216/267/327m³/h Inclination angle 45 ° retaining edge 120/160/200/240: 137/175/216/271m³/h Inclination angle 60° retaining edge 120/160/200/240: 96/124/153/197m³/h |

1000 | 1400 |

| LAD-1200 | Inclination angle 30 ° retaining edge 160/200/240/300: 275/331/419/466m³/h Inclination angle 45 ° retaining edge 160/200/240/300: 222/267/347/384m³/h Inclination angle 60° retaining edge 160/200/240/300: 158/190/253/178m³/h |

1200 | 1690 |

| LAD-1400 | Inclination angle 30 ° retaining edge 160/200/240/300/400: 319/395/500/564/794m³/h Inclination angle 45 ° retaining edge 160/200/240/300/400: 258/318/414/465/680m³/h Inclination angle 60 ° eretaining edge 160/200/240/300/400: 184/226/302/337/524m³ /h |

1400 | 1890 |

large inclination belt conveyor is mainly composed of conveyor belt, conveyor roller, transmission device, support device, guiding device and so on.

1) Conveyor belt: large inclination belt conveyor adopts special structure of conveyor belt, which is usually composed of transverse tie rod, longitudinal rubber belt and transverse rubber belt. The transverse tie bar is used to enhance the transverse rigidity of the conveyor belt, the longitudinal rubber belt is used to provide material carrying capacity, and the transverse rubber belt is used to prevent material overflow.

2) Conveyor Roller: The conveyor roller is the key component to support the conveyor belt, which consists of the carrier roller and the driving roller. The rollers are used to support the conveyor belt, and the drive roller is used to drive the conveyor belt movement.

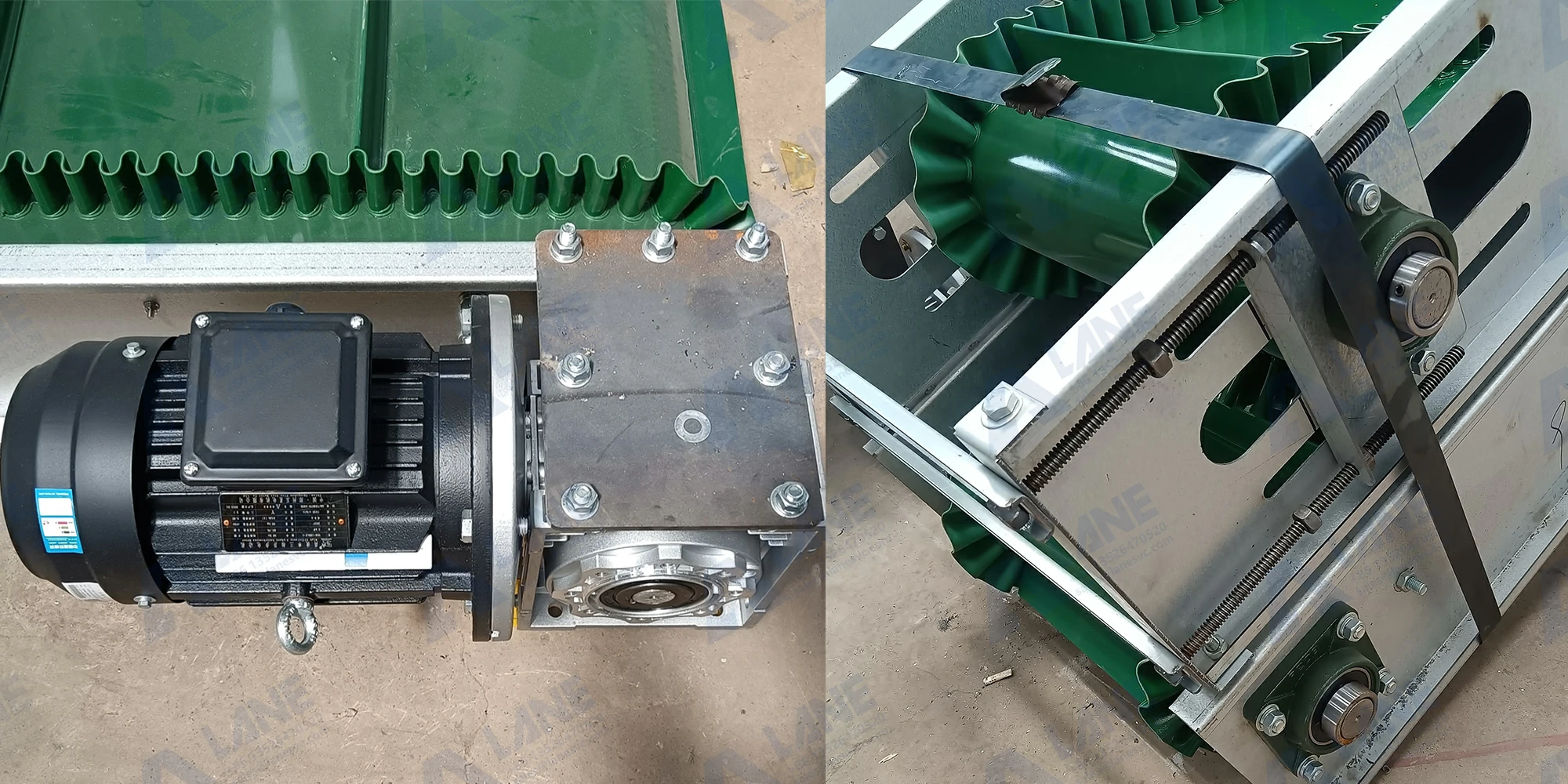

3) Transmission device: The transmission device mainly consists of motor, reducer and coupling. The motor transmits the power to the driving roller through the reducer and coupling to drive the conveyor belt.

4) Support device: the support device is used to support the conveyor belt of large inclination belt conveyor, usually composed of support frame and support leg. The support frame is fixed on the ground, and the support legs can be adjusted according to the need to ensure the level and stability of the conveyor belt.

5) Guiding device: The guiding device is used to prevent the conveyor belt from deviating and ensure the smooth transportation of materials. Usually adopts guide roller or guide plate.

1) When the conveyor belt is started, the motor drives the reducer and coupling to drive the driving roller to rotate, thus driving the conveyor belt movement.

2) After the material enters the conveyor belt from the feeding end, it is supported by the horizontal baffle plate on the belt and gradually moves to the discharging end along the movement direction of the conveyor belt.

1) Strong large inclination angle conveying capacity: large inclination angle belt conveyor can realize large inclination angle conveying, the maximum inclination angle can reach 90 degrees. This makes it can effectively solve the problem that traditional conveying equipment can not convey materials with large inclination angle.

2) Small footprint: large inclined angle belt conveyor has compact structure, small footprint, suitable for installation and arrangement in limited space.

3) Stable and reliable operation: the large inclination belt conveyor adopts high-quality transmission device and support device, stable and reliable operation, low failure rate and low maintenance cost.