Food is fundamental to economic development, and with fertilizer being the most efficient product for promoting a good food harvest, agriculture cannot thrive without the assistance of the fertilizer industry.

Nowadays, countries all over the world are making great efforts to develop their agricultural economies, and fertilizers have become an indispensable necessity for development.

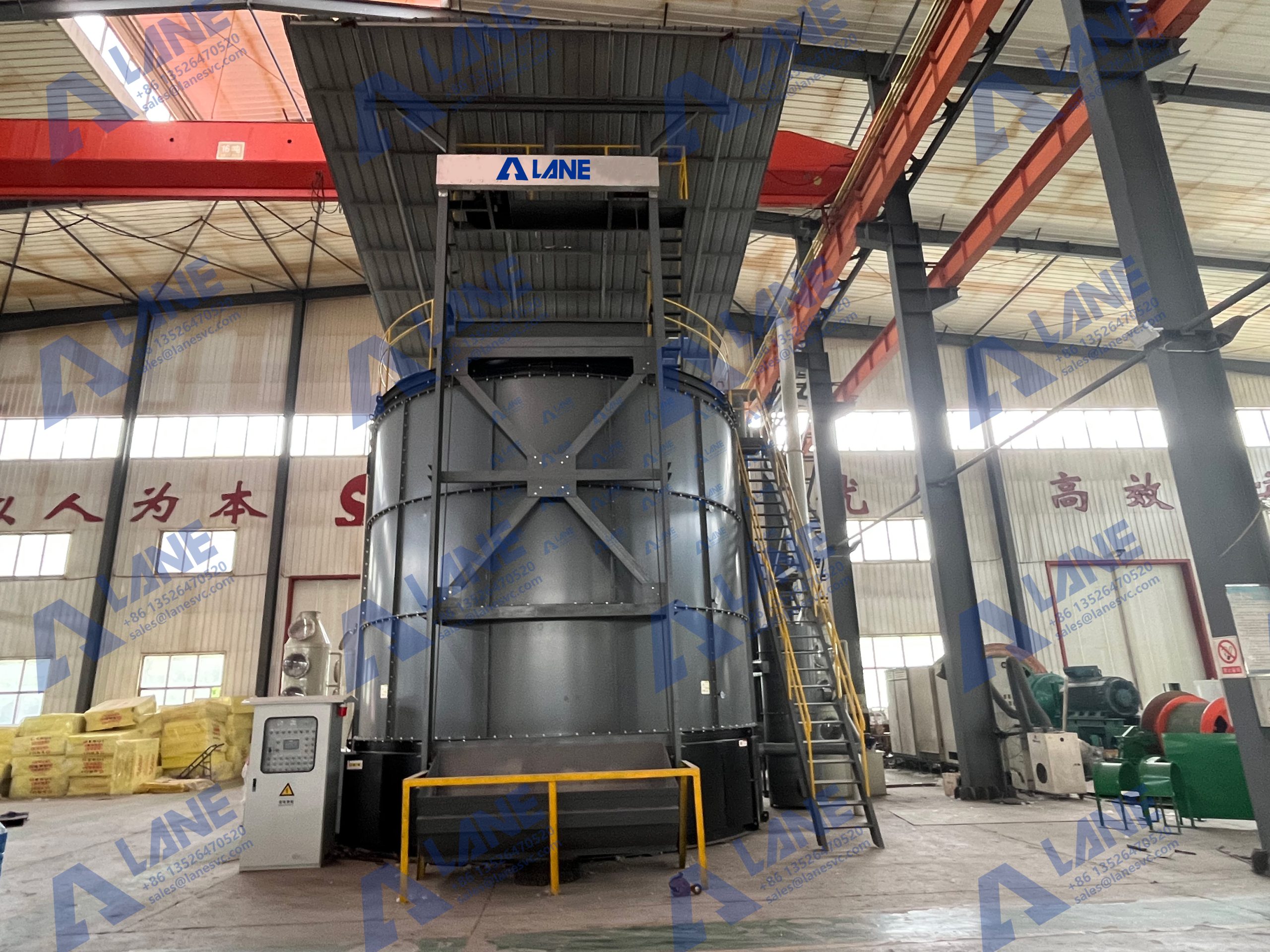

Lane Heavy Industry Technology, as a manufacturer who has been deeply involved in the fertilizer equipment manufacturing industry for more than 20 years, we have a wealth of experience.

If you are considering starting your own fertilizer production project, this guide will walk you through the basic steps needed to build a successful fertilizer plant.

Before starting your fertilizer production project, you need to determine the type of fertilizer you want to produce based on the requirements or conditions.

Fertilizers are usually divided into two main categories: organic fertilizers and inorganic (chemical) fertilizers. Each type requires different raw materials and processes, which will affect plant design and equipment selection.

Organic fertilizer:

1. Derived from plant, animal or industrial waste.

2. Requires composting, fermentation and drying processes.

3. Fertilizer efficiency is lower than chemical fertilizers, but it is ecologically friendly, and the demand for it is increasing due to the growing concern for environmental sustainability.

Inorganic fertilizer(Chemical fertilizer):

1. Produced by chemical reaction, or made by direct granulation of chemical powder.

2. Usually requires a mixture of various chemicals such as nitrogen, phosphorus and potassium (NPK).

3. The production process needs to be precisely controlled and raw materials accurately proportioned to ensure product consistency and optimal nutrient requirements for the soil.

Fertilizer production is a long and lasting project, and before investing in equipment and facilities, you need to identify some important things, which include:

1. The purpose of your project: to start a fertilizer business or to produce for your own use.

2. The needs of the target market: what type of fertilizer you need to produce? What is the capacity? What are your customers’ needs?

3. Regulatory requirements: Different regions may have different regulations for fertilizer production. Make sure you understand local laws and environmental standards.

4. Raw materials: Is there enough raw material to meet the continuous production of fertilizer?

Understanding these factors will help us to customize a fertilizer production line solution for you.

The next step is to decide on the type of fertilizer you want to produce and the method of production:

1. Granular fertilizers: easy to apply, shelf-life plant, variety, easy to transport, is the first choice for the type of fertilizer to be sold.

2. Liquid fertilizer: fast-acting, for more precise fertilization, usually through the irrigation system, the process is more complex, the product value is higher.

3. Biological compost: no need for granulation, raw materials are inexpensive, after aerobic or anaerobic decomposition process, the formation of compost with nutrients, can also be used as a raw material for organic fertilizer granulation to produce granular organic fertilizer.

The efficient production of fertilizer requires the selection of the right machinery and equipment for the production process. Key equipment includes

1. Crushers and mills: Used to grind raw materials.

2. Mixers: For mixing various ingredients.

3. Granulator: for producing granular fertilizers.

4. Dryers and coolers: for processing granular fertilizers and maintaining product quality.

5. Packaging machine: To ensure proper packaging of the final product.

If you plan to produce liquid fertilizers, you will need the following special equipment:

1. Mixing tanks: for mixing liquid nutrients.

2. Filtration system: to ensure that the liquid fertilizer is free from impurities.

3. Filling machine: for accurate packaging of liquid fertilizers.

If you plan to produce compost or organic fertilizer from compost, you will need the following specialized equipment:

1. Compost Turner: used for aerobic composting of organic waste, and at the same time, it has certain mixing and crushing effect, which can fully process a large amount of raw materials.

2. Fertilizer fermenter: used for anaerobic composting of organic waste, which can control the temperature and humidity to achieve the ideal composting effect.

The location of a fertilizer production plant is critical to the overall success of the project. The following factors should be considered when selecting a site:

1. Proximity to raw material sources: Easy access to raw materials can greatly reduce transportation costs.

2. Compliance: Because the operation of large industrial equipment generates noise, dust, and other pollution, your facility must comply with local zoning laws, environmental regulations, and safety standards.

3. Fertilizer Facility Design: Confirm the size of your production area, electricity standards, and other relevant information. Don’t worry about production issues, as long as you provide us with your exact requirements, our engineers will design a production plan that meets your expectations and customize each individual piece of equipment in your fertilizer production line to ensure it meets your production needs.

Implementation of quality control systems

Maintaining a high quality product is critical to the success of a fertilizer producer. Implement a robust quality control (QC) system to ensure that the fertilizer you produce meets industry standards and customer expectations. This should include

1. raw material inspection: check the quality of incoming raw materials (we can provide raw material testing equipment).

2. Process monitoring: Regular monitoring of the production process to ensure consistency (all production lines can be equipped with PLC control systems to ensure stable production).

3. end product testing: testing the nutrient content, texture and purity of the finished fertilizer (we can carry out granulation tests on your raw materials free of charge to ensure that the finished product meets your needs).

Staff and training in the fertilizer production line

The success of launching a fertilizer manufacturing business depends on a skilled workforce. If you don’t have the relevant experience, our company can provide you with professional technical guidance and documentation, as well as on-site installation and testing services by experienced overseas engineers.

No matter what problems you encounter in subsequent production, you can communicate with our one-on-one after-sales team, and we will try our best to solve the operation or quality problems of fertilizer equipment for you.

If you are interested in learning how to manufacture fertilizer and are ready to invest in a new project, here are the conventional fertilizer production lines we offer:

Organic fertilizer production line

NPK fertilizer production line

Compound fertilizer production line

Liquid fertilizer production line

If you have any other special production needs, we can provide the expertise to solve your fertilizer production challenges! Feel free to contact us!