author: Zero Shen

from: LANE Machinery Groups

The Fertilizer Granulation Machine market has witnessed remarkable advancements, with various models showcasing distinct features catering to diverse needs. In this report, we delve into the specifics, emphasizing the key characteristics that set these machines apart.

New type Organic Fertilizer Granulator is a kind of fertilizer granulation machine commonly used to produce granular organic fertilizers, and its main function is to form granules from raw materials through the process of mixing, compaction, extrusion and so on.

Its main function is to form granules through the process of compaction and extrusion of raw materials. Its stirring teeth can mix, blend and cut the organic raw materials with high humidity to form preliminary granules, and not only this, it is also suitable for the granulation of other inorganic raw materials.

Raw Material Compatibility: The churning teeth inside the new type organic fertilizer granulator can handle organic raw materials with high humidity, which is very suitable for manufacturing organic fertilizer granules.

Performance Highlights: It can efficiently convert raw materials into granules. The design of the churning teeth device makes the raw materials fully agitated and extruded to ensure the uniform composition of the granules, which is conducive to the absorption of nutrients by plants.

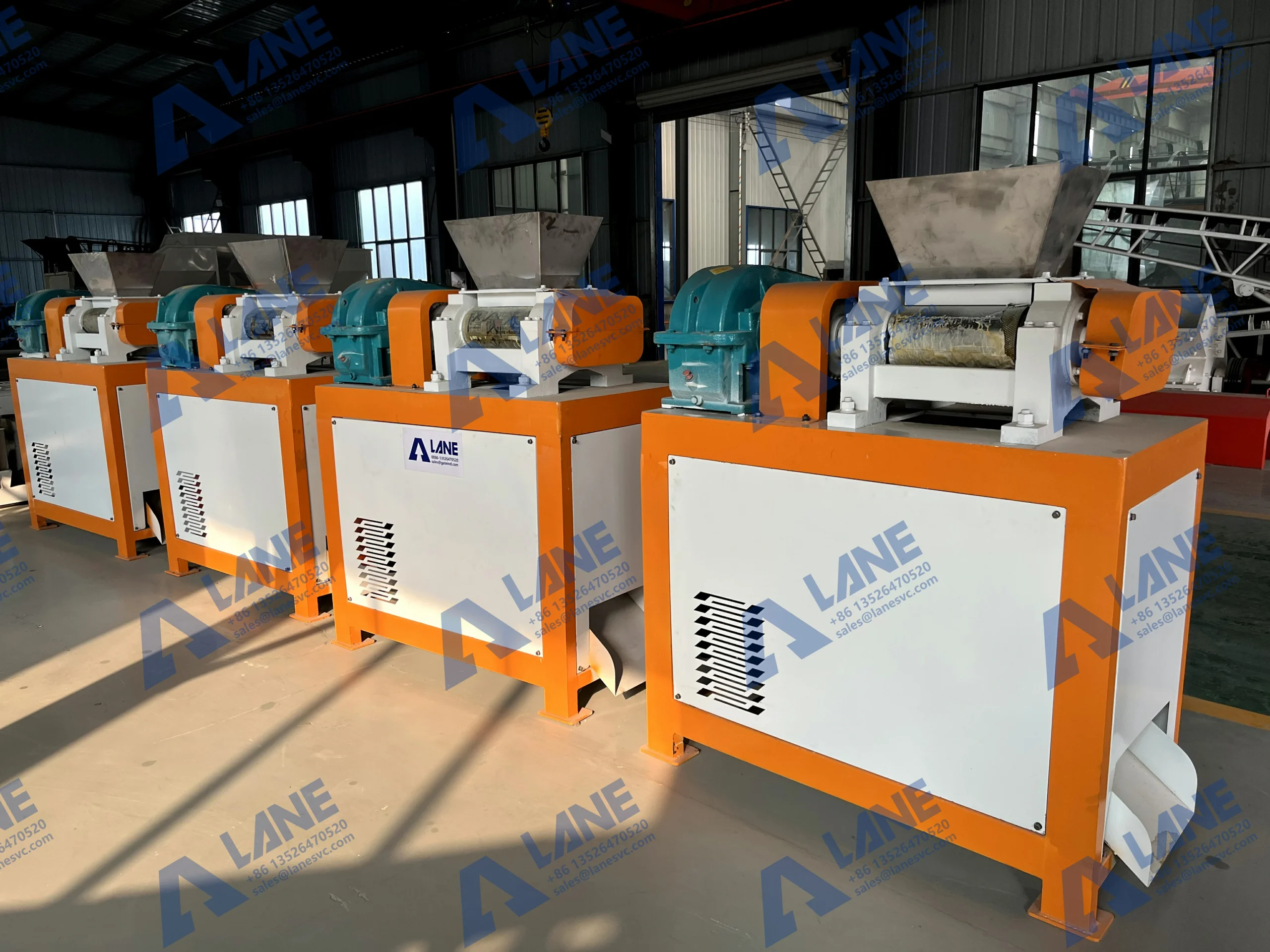

Double roller granulator is the key fertilizer granulation machine commonly used in compound fertilizer production line and NPK fertilizer production line. It is characterized by advanced technology, compact structure and low energy consumption. It can be matched with corresponding equipment to form a small production line, forming a certain capacity of continuous, mechanized production.

Raw Material Compatibility: Excelling with materials that are difficult to pelletize, the Double Roller Extrusion Granulator is the go-to choice for compound fertilizer production.

Performance Highlights: Recognized for its energy-efficient design, this machine ensures high-density granules, reducing fertilizer runoff and environmental impact.

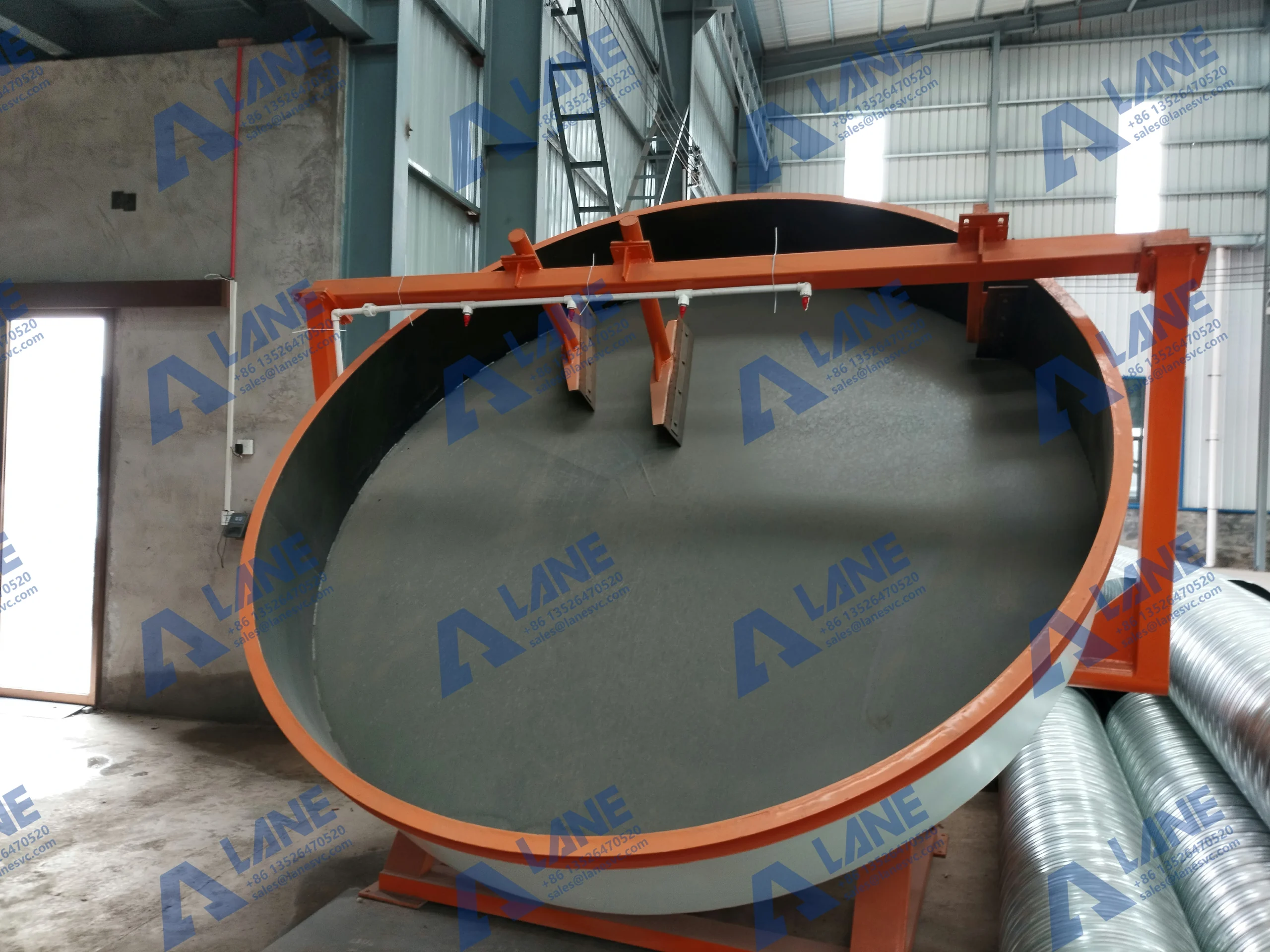

Disc granulator is a big pan-shaped machine set on top of a hard base plate. You can use it to make round pellets of assorted materials. Together with other fertilizer making machines, you can form a highly efficient fertilizer production line with a disc fertilizer compost granulator. Disc granulator is resistant and has a long service life. resistant and has a long service life, which makes it popular.

Raw Material Compatibility: Particularly effective for processing fine powders, the Disc Granulator is ideal for materials requiring careful handling due to its gentle granulation process.

Performance Highlights: Renowned for its cost-effective operation, this model stands out with its precise control over granule size and shape, promoting even distribution in the field.

Rotary drum granulator is a kind of fertilizer granulation machine which can make material into specific shape, which is suitable for cold and hot granulation as well as large-scale production of high, medium and low concentration compound fertilizer. Its main working method is wet granulation, with the help of the rotating movement of the cylinder, so that the material particles produced between the squeezing pressure agglomeration into a ball.

Raw Material Compatibility: Versatile and accommodating, the Rotary Drum Granulator excels with a wide range of raw materials, including both organic and inorganic components.

Performance Highlights: Known for its high granulation efficiency, this machine ensures uniform particle size and a smooth, spherical shape, optimizing nutrient release during plant uptake.

Flat die granulator is a kind of commonly used fertilizer granulation machine, mainly used for powder or granular materials for granulation processing, the loose powder materials through the action of pressure and friction into a certain shape and size of the particles. Commonly used in fertilizer production line , feed production line and cat litter production line, etc.

Raw Material Compatibility: Tailored specifically for organic materials, the Pan Granulator excels in handling compost, poultry manure, and other bio-based substrates.

Performance Highlights: With its robust structure and easy maintenance, this model offers reliability and consistency in granule production, contributing to sustainable agricultural practices.

In the dynamic realm of agriculture, understanding the characteristics of different Fertilizer Granulation Machines is crucial for farmers seeking optimal soil fertility solutions. As we navigate through these innovative technologies, it becomes evident that the choice of granulation machine profoundly influences crop productivity and environmental sustainability.

We have a wealth of experience in the transaction of fertilizer granulation machine, according to the customer’s use of feedback and continuous improvement, and now has mastered a fairly mature technology. If there is any question about the product, you are welcome to inquire! We look forward to starting a win-win cooperation journey with you!

welcome to contact us!