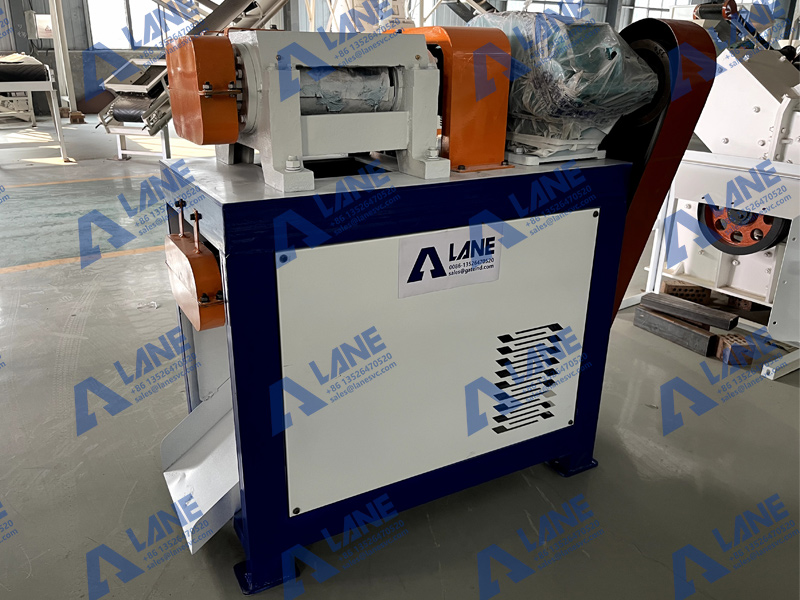

In fertilizer production, Double Roller Granulator are commonly used to compact and shape fertilizer materials into granules, which is widely used in npk fertilizer production line.

While these machines are efficient and effective, they can encounter several problems with their rollers over time.Some of the major issues that can occur in the rollers of double roller granulators include:

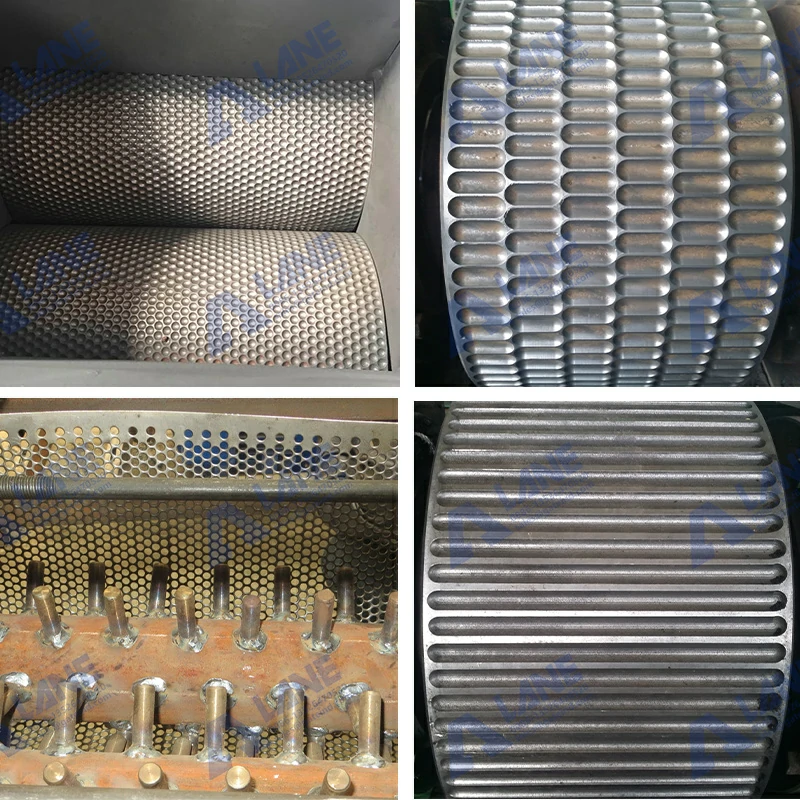

Rollers of double roller granulators experience wear and abrasion due to continuous friction and pressure during the granulation process. This leads to reduced efficiency and potential deterioration of granule quality.

Solution:

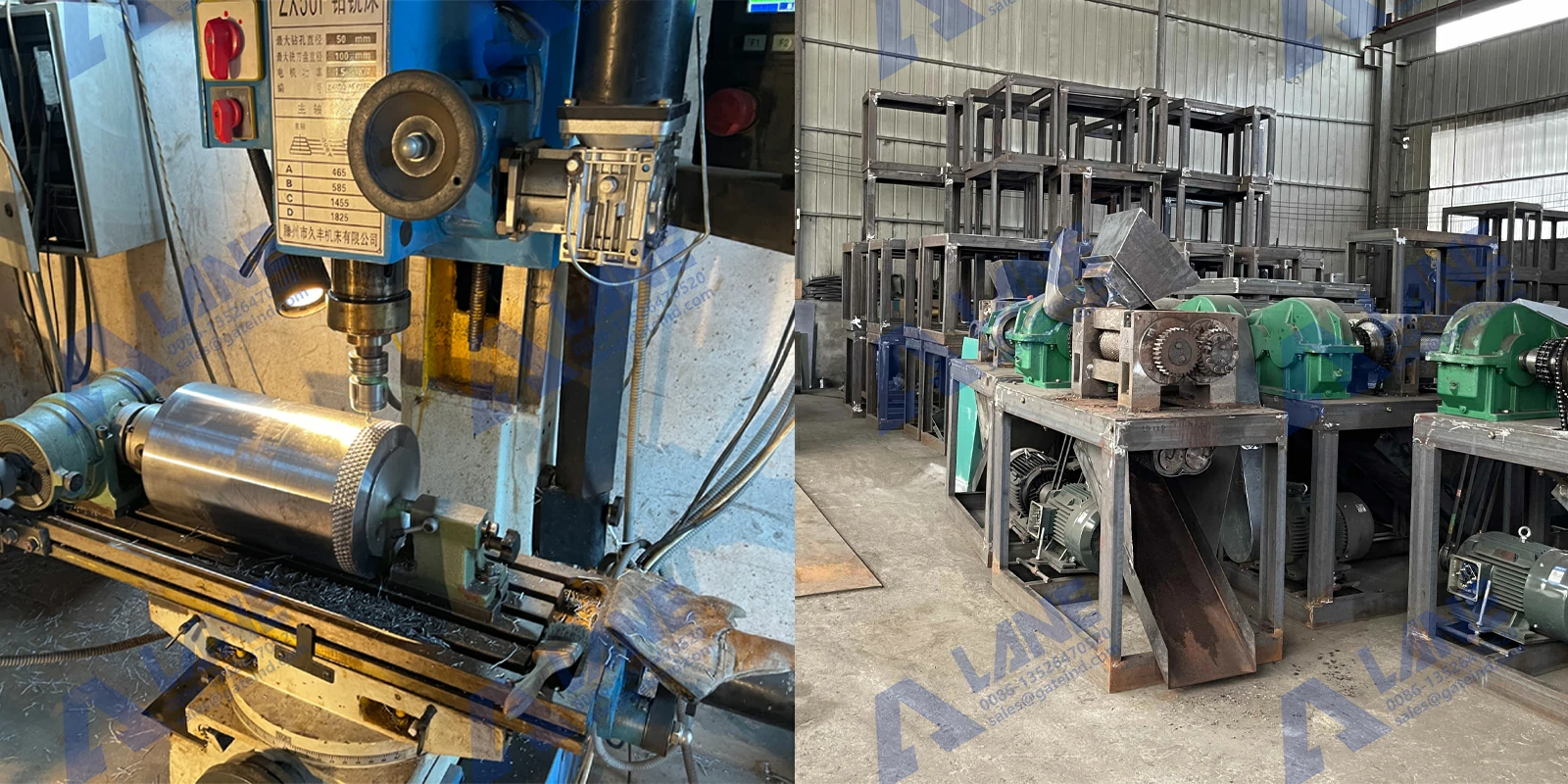

Material Selection: Choose rollers made from wear-resistant materials such as hardened steel or specialized alloys.

Regular Inspection: Implement a schedule for inspecting roller wear. Replace worn rollers promptly to maintain granulation effectiveness.

Optimize Pressure: Adjust pressure settings carefully to balance efficient compaction and minimized wear.

Intense pressure and stress on the rollers can cause cracks or even breakage, compromising both granulation quality and machine integrity.

Solution:

Appropriate Roller Selection: Choose rollers with suitable material properties and thickness to withstand the applied pressure.

Stress Monitoring: Regularly monitor roller stress levels and adjust process parameters if needed to prevent excessive pressure.

Insufficient or improper lubrication can result in increased friction and wear on roller components, reducing granulator efficiency

Solution:

Scheduled Lubrication: Implement a regular lubrication schedule using appropriate lubricants for roller bearings and moving parts.

Effectiveness Monitoring: Monitor the effectiveness of lubrication and adjust the frequency if needed.

Temperature fluctuations during the granulation process can impact the structural integrity of rollers and affect granule formation.

Solution:

Temperature-Resistant Rollers: Choose rollers designed to withstand the temperature variations encountered during the granulation process.

Temperature Control: Implement temperature controls within the granulation process to maintain a stable operating environment.

The Rollers of Double Roller Granulators are not mere components; they are the artisans shaping the future of fertilizer granulation. Their precision, adaptability, and efficiency make them an integral part of a sophisticated machinery ensemble, contributing to the production of top-notch fertilizers for the agricultural landscape.