For farmers battling nutrient waste and environmental pressures, sulfur-coated urea (SCU) delivers tangible, cost-effective solutions. Unlike futuristic promises, SCU leverages established science: a physical barrier of sulfur controls nitrogen release, matching plant uptake. This translates directly to reduced fertilizer applications (typically 15-30%), minimized nitrate leaching and greenhouse gas emissions, and significant cost savings per hectare – a compelling value proposition grounded in reality.

Manufacturing high-performance SCU isn’t about complexity; it’s about precision engineering and robust execution. The proven process flow is straightforward yet demands excellence at each stage:

Preheating: Urea prills are gently heated to optimize surface adhesion.

Sulfur Melting & Filtration: Molten sulfur (>99.5% purity) is maintained at precise temperatures (140-150°C) and rigorously filtered to ensure coating integrity.

Coating: Preheated urea prills enter a high-speed rotary drum coater. Molten sulfur is sprayed uniformly onto the cascading prills under controlled conditions.

Cooling: Hot coated prills are efficiently cooled in a dedicated rotary cooler, solidifying the sulfur layer without cracking.

Sealant Application (Critical Step): A micro-thin polymer sealant (e.g., polyethylene or proprietary blends) is applied. This step is non-negotiable for preventing premature nitrogen release caused by micro-cracks inherent in sulfur.

Conditioning & Curing: Prills are conditioned to stabilize the coating and promote curing, enhancing handling properties and release characteristics.

Screening & Packaging: Oversize and undersize particles are removed, ensuring consistent product size before bulk or bagged packaging.

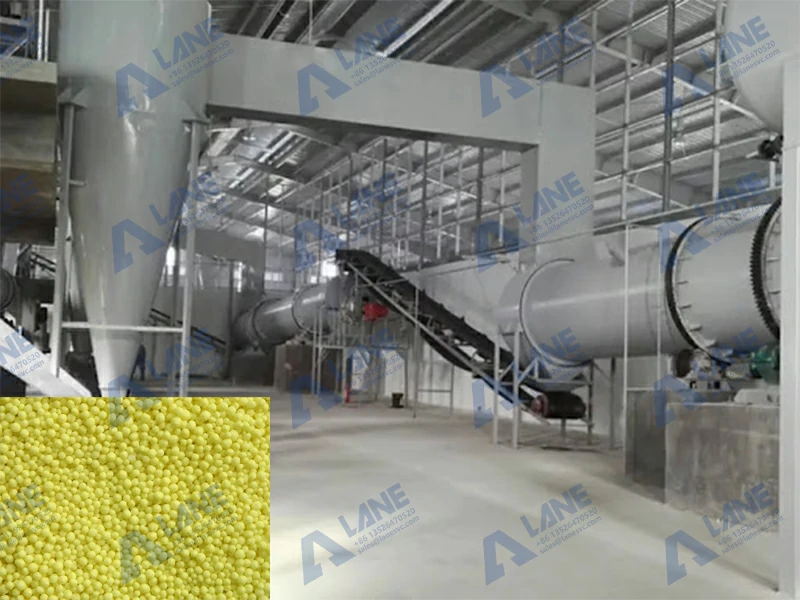

The Difference is in the Drum: Our Proven Production Line

At LANE, we don’t just build machines; we engineer reliable sulfur-coated urea production line focused on coating uniformity, efficiency, and product longevity. Our core coater technology delivers:

Unmatched Coating Uniformity: Advanced drum design and spray systems ensure consistent sulfur thickness (target 20-40 microns) across every prill, batch after batch. Achieving >95% coating uniformity.

Robust Sealant Integration: Precision application systems guarantee complete, micro-thin sealant coverage, directly translating to predictable, extended nitrogen release profiles.

High Capacity & Efficiency: Engineered for continuous, high-volume production. *Typical lines produce 10-25 tons per hour (TPH), scalable to 200,000+ tons per annum.*

Operational Efficiency: Optimized thermal management and process control minimize energy consumption (< 35 kWh per ton product) and maximize uptime.

Durability for Harsh Environments: Heavy-duty construction using corrosion-resistant materials ensures longevity, especially crucial in demanding settings like the Middle East.

Proven Success: Our Flagship sulfur-coated urea Plant in the Middle East

Facing intense heat, water scarcity, and the need for efficient nutrient use, a major fertilizer producer in Oman chose our complete turnkey SCU production solution. The challenge: build a reliable, high-capacity plant (20 TPH) leveraging local sulfur resources to serve regional agriculture.

The Outcome:

Reliable Operation: The plant consistently meets its design capacity of 160,000 tons per year, operating efficiently in the demanding Gulf climate.

Premium Product Quality: Rigorous testing confirms coating uniformity exceeding 96% and nitrogen release curves matching target specifications (e.g., 30-40% release in 7 days, 80%+ by 60-90 days).

Market Impact: “Integrating LANE’s coater technology was critical,” stated the Plant Manager. “The precision of the sulfur application and, crucially, the sealant system, gives us a product farmers trust. We see demand growing steadily because it works – growers report using less fertilizer while maintaining or increasing yields, and they value the reduction in field passes.”

Why Partner with Us for Your Sulfur-coated Urea Production?

Decades of Core Technology Focus: We specialize in the essential coating and sealing technology that defines sulfur-coated urea performance.

Proven Plant Performance: Our references, like the Oman facility, demonstrate reliable, high-output production under real-world conditions.

Engineered for Value: We deliver robust, efficient lines focused on your ROI, minimizing operational costs and maximizing product quality.

Deep Regional Understanding: We have hands-on experience delivering and supporting plants in challenging environments like the Middle East.

Ready to Produce High-Performance Sulfur-coated Urea?

Move beyond theory. Leverage our engineered solutions and proven track record to manufacture sulfur-coated urea that delivers real agronomic and economic benefits. Contact our engineering team today to discuss your project requirements.

Follow Us:

LANE Linkin

YOUTUBE

WhatsApp