Lignite is one of the most abundant and low-cost carbon-based raw materials in the world. However, due to its hard structure and low biological activity, its commercial utilization has long been underestimated.

With advanced processing technology, lignite can be effectively converted into high-quality humic organic fertilizer with strong global market demand.

LANE’s Lignite Organic Fertilizer Machine is specially developed to unlock the full potential of lignite and help investors, fertilizer plants, and mining companies build profitable lignite-based organic fertilizer projects.

Lignite (brown coal) is an excellent raw material for organic fertilizer production because of its unique properties:

High humic acid content (30%–60%)

Strong cation exchange capacity (CEC)

Excellent soil structure improvement ability

Rich organic carbon source

Low mining cost and wide global distribution

Compared with peat and leonardite, lignite offers a more stable supply and lower raw material cost, making it highly suitable for large-scale fertilizer production using a Lignite Organic Fertilizer Machine.

Despite its advantages, raw lignite also presents several processing difficulties:

Poor water solubility of humic acid

Dense molecular structure, difficult to decompose

Low microbial activity without activation

This is exactly why ordinary fertilizer equipment fails to process lignite efficiently — and why a dedicated lignite organic fertilizer machine is required.

LANE has developed a specialized lignite organic fertilizer machine, designed specifically for lignite characteristics.

LANE’s heavy-duty lignite crusher breaks lignite into fine particles, increasing contact surface area.

The integrated humic acid activation system opens the molecular structure, improving chemical reactivity and microbial accessibility.

Improves lignite decomposition efficiency

Prepares material for fermentation and granulation

Lignite is fermented together with organic materials such as:

Livestock and poultry manure

Sugar by-products

Urea or ammonium sulfate

Functional microbial strains

This step significantly increases organic matter content, microbial activity, and nutrient availability.

Enhances fertilizer efficiency

Improves soil biological activity

LANE’s patented humic acid activation technology significantly improves:

Water-soluble humic acid content

Fulvic acid proportion

Soil absorption efficiency

Compared with conventional fertilizer machines, LANE’s Lignite Organic Fertilizer Machine increases water-soluble humic acid by 20%–35%, making the final product more effective and market-competitive.

LANE offers multiple granulation solutions depending on product type:

Disc granulator (round granules)

New-type organic fertilizer granulator

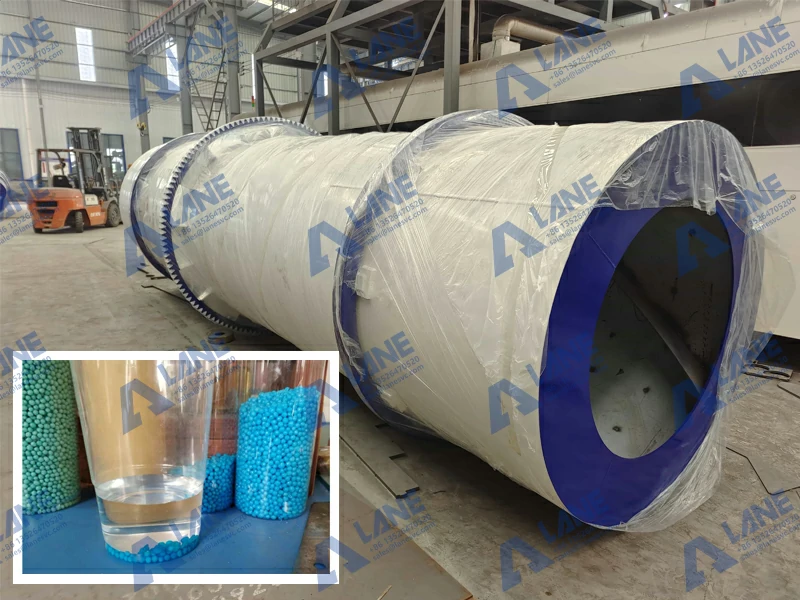

Drum granulator for compound formulas

Uniform granule size

High granule strength

Excellent appearance for commercial sales

The rotary drum dryer and cooler:

Reduce moisture to standard levels

Prevent caking and moisture regain

Improve storage and transportation stability

This ensures lignite fertilizer granules maintain quality during long-distance export.

Final fertilizer granules are:

Screened for size uniformity

Optionally coated to improve appearance and nutrient retention

Automatically weighed and bagged (25kg / 50kg / jumbo bags)

Ready for wholesale and retail markets.

Unlike general organic fertilizer equipment, LANE’s lignite organic fertilizer machine is engineered to handle:

High hardness materials

Low degradability lignite

High humic acid structures

LANE’s system maximizes humic acid utilization, producing fertilizer with higher agronomic value and better market pricing.

Lignite raw material cost is significantly lower than peat or leonardite

Energy-saving system reduces operating costs

Total production cost reduced by 15%–20%

This makes lignite fertilizer projects highly attractive for long-term investment.

LANE provides lignite organic fertilizer production lines with capacities from:

1 T/H (small plants, farms)

5–10 T/H (medium fertilizer factories)

15–20 T/H (industrial-scale production)

LANE offers complete project support:

Raw material testing & analysis

Customized process design

Plant layout & civil guidance

Equipment manufacturing

Installation & commissioning

Operator training & after-sales service

Products produced by a Lignite Organic Fertilizer Machine are widely used in:

Soil improvement and soil remediation

Saline-alkali land restoration

Cash crops (vegetables, fruits, tea, coffee)

Grain crops (wheat, corn, rice)

Greenhouses and horticulture

Organic agriculture bases

With the global demand for humic acid fertilizer continuously increasing, lignite-based organic fertilizer has become one of the most profitable organic fertilizer categories.

If you have access to lignite resources, now is the best time to convert them into high-value fertilizer products.

LANE’s Lignite Organic Fertilizer Machine helps you transform low-cost lignite into premium humic organic fertilizer with strong market demand and high profit margins.

Tell us your:

Raw material type

Required capacity

Investment budget

Our engineers will design a customized lignite organic fertilizer solution for you within 24 hours.